-

Horizon iCE StitchLiner Mark V Saddlestitcher

GM-HOR-SPF50D- Individual creasing and scoring: Dual creasing rollers at the in-feed crease every sheet individually before they are folded and accumulated, making tighter, flatter booklets and increasing fold accuracy. Individual sheet creasing and stream folding eliminates the need for sub-setting on higher pager counts, increasing productivity for booklets as high as 200 pages.

- Stable sheet transport: A newly designed sheet register allows for more stable transportation of a wider range of paper stocks, including very thin stocks, and a redesign of the accumulating section significantly reduces static build-up between pages, ensuring continuous production.

- No manual touchpoints: Variable production on the Mark V is fully automated, requiring no operator intervention whatsoever. The system can automatically change stitch length, belt and roller pressure, and registration control in the trimmer based on page count.

- Optional cover feeding: The optional dual-bin cover feeder merges covers into the print stream without affecting production speed. Additionally, up to three dual-bin feeders can be combined in one system allowing for the pre-staging of covers and the option to interpose up to 3 sheets anywhere within the booklet. This feeder can also function as a digital feeder to expand production capabilities.

- Intelligent tracking: The Mark V’s tracking system ensures booklet integrity with optional barcode reading, cover and book block matching, sheet separation verification, and automated rejection of booklets with detected errors.

HIGH QUALITY

Newly designed saddle-stitching system achieves high

quality booklet production at a high speed. The sheets

are tightly folded along the accurate scoring lines made

one by one for consistent quality production without

any special skill.

HIGH PRODUCTIVITY

Newly developed sheet transport system enables

smooth and stable transportation of thin sheets at a

high speed. The system can produce 6,000 booklets

per hour at maximum.

VARIABLE DATA HANDLING

Variable page count applications can be handled

without any operator intervention. The in-line

confi guration insures sheet-to-sheet integrity.

FLEXIBLE INSERTION

The optional cover feeder CF-50D enables fl exible

insertion of up to 3 sheets in the booklet. The top-feed

mechanism enables smooth sheet insertion of a wide

variety of sheets.

FORMAT EXPANSION

Expanded format size to meet A4 landscape large

format calendar production. Higher productivity is

achieved on a wider range of formats, including A4

landscape at over 5,000 per hour.

MANAGE YOUR BINDERY WITH HORIZON’S BINDERY

CONTROL SYSTEM

The iCE Series can be enhanced with automated

workfl ow from upstream to post-press with iCE LiNK,

which uses cloud technology, Horizon’s next generation

bindery control system.Sheet Size:20″ W x 14.015″ L (Portrait max)24″ W x 10.510″ L (Landscape max)7.640″ W x 5.515″ L (Min)Booklet Size (Untrimmed):14.015″ W x 10″ L (Portrait max)10.510″ W x 12.005″ L (Landscape max)5.515″ W x 3.820″ L (Min)Booklet Size (Trimmed):13.855″ W x 9.920″ L (Portrait max)10.350″ W x 11.925″ L (Landscape max)4.725″ W x 3.350″ L (Min)Sheet Weight (Roll paper):52.3 to 209 gsm (Normal)73.3 to 209 gsm (Coated)Sheet Weight (Cover):52.3 to 350 gsm (Normal)73.3 to 350 gsm (Coated)Stitching Wire: 0.4mm – 0.6mmProduction Speed: Up to 6,000 booklets/hourIssue rendering sageThe iCE StitchLiner Mark V Saddlestitcher from Standard Horizon was specially designed to run inline or near-line with high-speed, roll-fed digital presses. This automated saddlesticher produces high-quality booklets at speeds of up to 6,000 booklets/hour. Individual sheets are tightly folded along scoring lines for consistent quality, even with high page counts or variable page count applications. The Mark V also supports an optional cover feeder and can handle sheet sizes up 20” x 14” and produce a wide range of booklet sizes including A4 Landscape.

• Individual creasing and scoring

• Stable sheet transport

• Intelligent tracking -

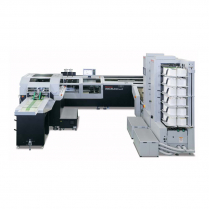

Horizon iCE StitchLiner Mark IV Saddlestitcher

GM-HOR-SPF50The iCE StitchLiner Mark IV Saddlestitcher is a third-generation saddlestitcher from Standard Horizon that combines the efficiency and ease of operation of flat-sheet collating with the productivity, versatility, and quality of a traditional saddlestitching system. All processes, including signature scoring and folding, saddlestitching, and three-knife trimming are performed in one pass. The Mark IV can produce a wide range of applications, including A4 landscape booklets and pocket-sized booklets.

- Production speeds: The Mark IV can run at speeds of up to 6,000 booklets per hour for A4 portrait applications and 5,300 booklets per hour for A4 landscape applications.

- True variable production: Stitch length, balance adjustment, registration guides, trim size, and more can all be changed automatically from booklet to booklet during operation for true variable booklet production.

- Increased up-time: The Mark IV can maintain production speeds even while in variable thickness mode or when cover sheets are inserted. The Mark IV can also run continuously even if a booklet with an error such as a dropped stitch or sheet misalignment is detected by seamlessly rejecting the booklet to a tray.

- Consistent quality: The Mark IV can stitch booklets up to 10 mm thick (about 50 sheets at 50lb offset). Across all booklet sizes, the system’s scoring function reduces cracking on the spine and allows for a tighter fold. Depending on the substrate, the gap and scoring pressure can be adjusted for consistent scoring quality. The sheet-alignment section of the Mark IV features 4-directional jogging for a tighter jog and more accurate alignment across stocks. Improvements to the Mark IV’s transport system also allows for stable sheet transport across substrates, even for coated sheets.

- Flexible configuration: The iCE StitchLiner Mark IV can be integrated with VAC series collators and the HOF-400 High-speed Sheet Feeder. The feeding system and other optional devices can be configured depending on your specific needs, including for offset or digital print output. The Mark IV’s infeed height can be adjusted from 28.34” to 43.70” to allow for connections to various unwinders and cutters.

- iCE LiNK ready: The Mark IV is compatible with iCE LiNK, Horizon’s cloud-based workflow management system.

Sheet Size:14.0″ W x 20.0″ L (Portrait max)10.5″ W x 24.0″ L (Landscape max)5.5″ W x 7.6″ L (Min)Booklet Size (Untrimmed):14.0″ W x 10.0″ L (Portrait max)10.5″ W x 12.0″ L (Landscape max)5.5″ W x 3.8″ L (Min)Booklet Size (Trimmed):13.9″ W x 9.9″ L (Portrait max)10.4″ W x 11.9″ L (Landscape max)4.7″ W x 3.4″ L (Min)Sheet Weight Range:52.3 to 350 gsm (Normal)73.3 to 350 gsm (Coated)Fold Thickness:2mm/0.075″ (Max)Stitching Wire:0.5 mmProduction Speed:6,000 booklets/hour (A4 Portrait)5,3000 booklets/hour (A4 Landscape)Issue rendering sage

The Horizon iCE StitchLiner Mark IV Saddlestitcher is a high-speed, fully-automated booklet-making machine designed for commercial printing applications. The machine features advanced technology that ensures accurate stitching and folding of booklets at a rate of up to 6,000 booklets per hour. All processes, including signature scoring and folding, saddlestitching, and three-knife trimming are performed in one pass.The iCE StitchLiner Mark IV can handle a wide range of paper sizes including landscape and pocket-size booklets.

• Variable thickness production

• Production speed: 6,000 booklets/hr

• Up to 350 gsm

• iCE LINK ready -

Horizon FoldLiner

GM-HOR-FOLDLINERNEW HYBRID APPROACH TO SADDLE STITCHED BOOKLETS FROM PRESS SHEET

Eliminate the folding process and go from digital to off set press sheet to saddle stichted booklet using a single operator.

- No touch points: The Foldliner combines the AFC-74 Series Folder and the Stictchliner 6000 Saddle-Stitching System. No additional offline processing is required after printing for finishe booklet production.

- High Productivity: Flat sheet to saddle stitched booklet can be produced u to 6,000 booklets per hour.

- Variable Production: Variable sheet count production can be achieved by use of optimal mark sensor. Suitable for digitally printed B2 size sheet and full size press sheets.

Sheet Size Max 356(W) x 508(L) mm (14″ x 20″) Sheet Size Min 140(W) x 199(L) mm (4.7″ x 7.1″) Sheet Weight Range Normal: 53 to 157 gsm / Coated: 74 to 210 gsm Booklet Size Max (before trim) 350 x 250 mm (13.7″ x 9.8″) Booklet Size Min (before trim) 210 x 139.7 mm (8.3″ x 5.5″) Production Speed 6,000 booklets/hr max Issue rendering sage The new Horizon FoldLiner takes an innovative, hybrid approach, combining saddlestitching and folding to go from digital or offset press sheet to saddlestitched booklet in one efficient system.

The new Horizon FoldLiner takes an innovative, hybrid approach, combining saddlestitching and folding to go from digital or offset press sheet to saddlestitched booklet in one efficient system.

• High productivity

• Accommodates press sheets up to 40″

• Up to 6,000 booklets/hr

• Wide range of booklet sizes

• Covers can also be merged from the tower.

• Mark sensor

-

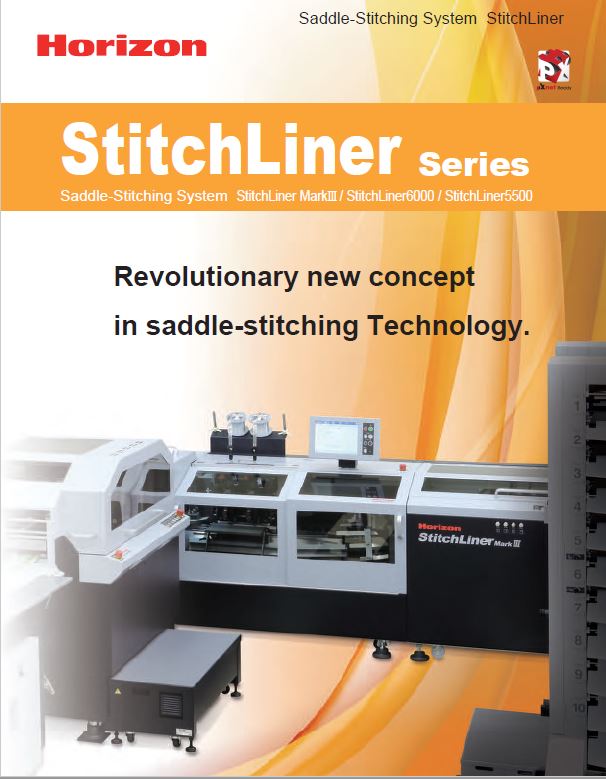

StitchLiner Mark III Stitcher

GM-HOR-SPF40

The Horizon Mark III is an advanced bindery machine that is designed to streamline the binding process for high-volume printing jobs. This machine is specifically designed for use in commercial printing environments where large volumes of paper need to be bound quickly and efficiently. It offers a range of binding options, including saddle stitching, side stitching, and perfect binding. This makes it an incredibly versatile machine that can handle a variety of binding tasks.

The StitchLiner Mark III features expanded booklet size and increased productivity up to 6,000 booklets per hour. The system can produce a wide range of applications, inclding landscape-size boolets, 12"x12" calendars and pocket booklets down to 4.5"x3.5". The Mark III offers fully automated setup, including stictching head settings with no manual adjustments required for book thickness at the trimmer, delivering higher quality booklets with greater efficiency, even for variable stitch length and variable page count booklets.

• Wide range of booklets: The system can produce a wide range of applications, including landscape-size booklets, 12” by 12” calendars, and pocket booklets down to 4.5” by 3.5”.

• Full automation: The StitchLiner Mark III offers a fully automated setup, including stitching head settings and adjusting book thickness at the trimmer, to deliver higher quality booklets with greater efficiency – even for variable stitch length and variable page count booklets.

Sheet Size: 5.5" x 7.6" to 14" x 20"

Stock Weights: Normal: 52.3 to 350 gsm / Coated: 73.3 to 350gsm

Booklet Size (before trim): 5.5 x 3.8" to 14 x 10"

Portrait Booklet Size (Finished): 4.725" x 3.350" to 13.855 x 9.920"

Landscape Booklet Size (Finished): 4.725" x 3.350" to 10.350 x 11.925"

Fold thickness: Max. : 2 mm or 0.075” (Thickness of one block)

Stitch Thickness: Max. 0.195” (Booklet Thickness: 0.390”); ~50sheets paper

A4 Portrait Production Speed: 6,000 booklets/hr max

A4 Landscape Production Speed: 5,300 booklets/hr

Electrical: 3-phase 200-230V, 50/60 HzIssue rendering sage The StitchLiner Mark III features expanded booklet size and increased productivity. It offers fully automated setup, delivering higher quality booklets with greater efficiency, even for variable stitch length and variable page count booklets.

The StitchLiner Mark III features expanded booklet size and increased productivity. It offers fully automated setup, delivering higher quality booklets with greater efficiency, even for variable stitch length and variable page count booklets.

• Paper sizes from 5.5” x 7.6” – 14” x 20”

• Book thickness up to 50 sheets/200 pages

• Production speed up to 6,000 booklets/hr -

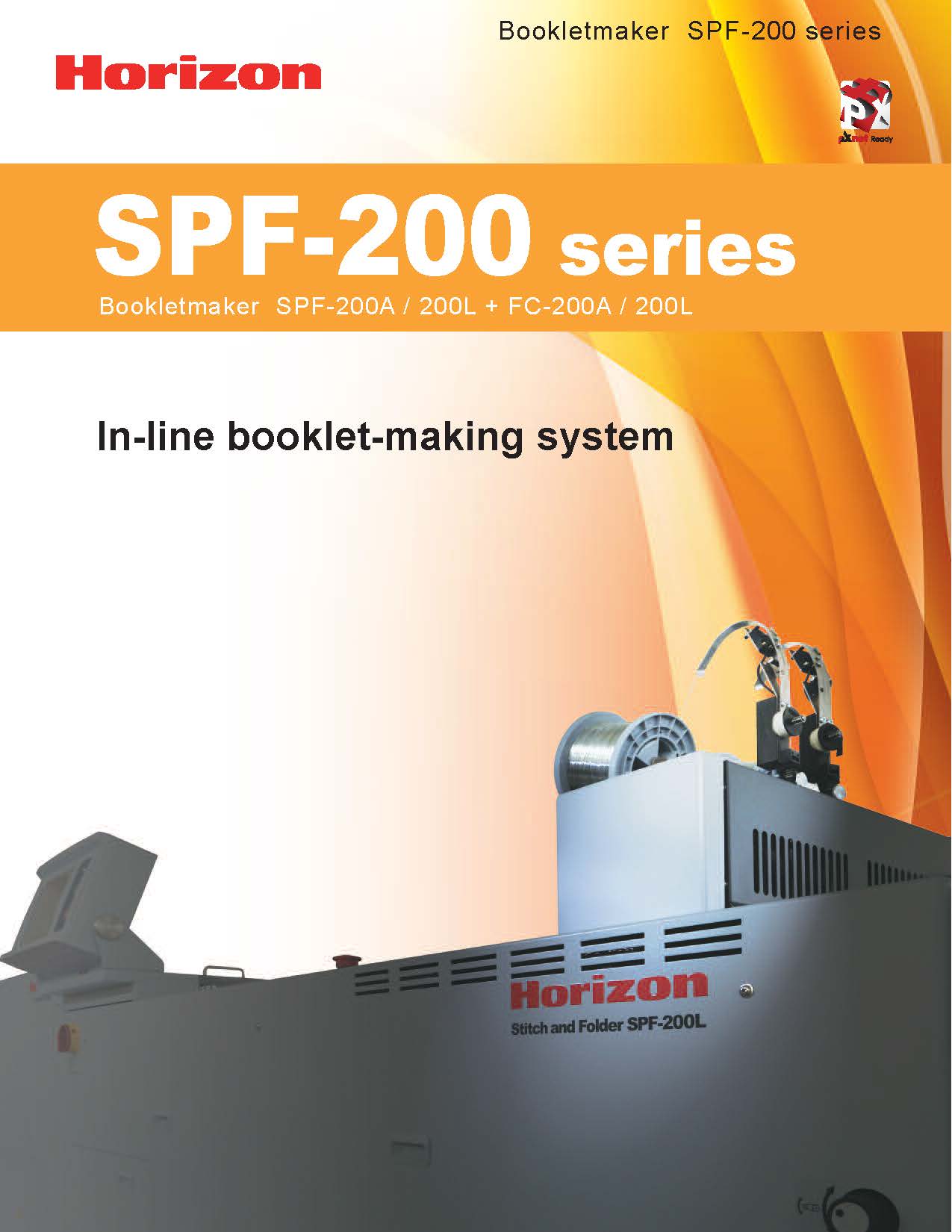

Horizon SPF-200L Automated Stitcher/Folder

GM-HOR-SPF200L

The Horizon SPF/FC-200L with HOF 400 is a fully automated landscape combination stitcher/folder and face trimmer. It is equipped with a user-friendly 10.4” intelligent color touch screen that provides advanced set-up automation and centralized control. The SPF/FC-200L features an integrated hand-marry station for increased flexibility and a built-in error eject tray which allows for non-stop production at speeds up to 4,500 booklets/hour. The HOF-400 is the latest in Horizon’s line of versatile sheet feeders. Variable page count production can be handled with integrity and verification using the standard mark reader.

- Landscape format support: The SPF-200L also features improved format flexibility including 8.5” x 11” landscape capabilities, ideal for producing landscape brochures or calendars.

- Easy to operate: Fully-automated set-up through the 10.4 inch color touch screen – including fold roller gap adjustment – ensures user-friendly and intuitive operation for professional quality booklet production at all skill levels.

- Digital and offset support: The system can accept digitally printed output from any of Standard’s HOF high-speed sheet feeders and can also serve conventional offset print needs when combined with a collating tower.

Max. sheet size: 14" x 24"

Min. sheet size: 4.7" x 7.1"

Max. paper thickness: 157 gsm

Min. paper thickness: 64 gsm

Max. Booklet size: 14" x 12"

Min. Booklet size: 4.7" x 3.5"

Speed: up to 4,500 booklets/ph

Display: 10.4" Color touch screen

Memory: 200 programmable jobs

Electrical: 220-240v, 1ph, 50/60hz

Machine Dimensions (LxWxH): 73.1 x 31.9 x 49.3" x 1,083.8 lbs.Operator's Manual

SpecificationsIssue rendering sage The Horizon SPF/FC-200L with HOF 400 is a fully automated landscape combination stitcher/folder and face trimmer.

The Horizon SPF/FC-200L with HOF 400 is a fully automated landscape combination stitcher/folder and face trimmer.

- Equipped with a user-friendly 10.4” color touch screen

- Advanced set-up automation and centralized control

-

Horizon SPF/FC-200A Bookletmaker

GM-HOR-SPF200AThe Horizon SPF/FC-200A is a fully-automated combination stitcher/folder and face trimmer that is equipped with a user-friendly 10.4″ intelligent color touchscreen that provides advanced set-up automation and centralized control.

- Easy, automated changeovers: The SPF/FC-200A brings bookletmaking automation and operator ease-of-use to new heights with quick and automated setups that include folder roller gap settings.

- Precision engineering: Precise stepper motors drive end stops, side guides, stitching heads and other systems to the exact location for the sheet size and finish style selected.

- Increase productivity: The SPF/FC-200A features an integrated hand-marry station for increased flexibility, and a built-in error eject tray which allows for non-stop production at speeds up to 4,500 booklets per hour.

Sheet Size 4.7″ x 7.1″ to 14″ x 20″ (W x L) Sheet Weight Range 64 to 157 gsm (normal paper), 84.9 to 157 gsm (art coated paper) Booklet Size 4.7″ x 3.5″ to 14″ x 10″ (W x L) Production Speed Up to 4,000 booklets/hour (A4-Finish, Portrait), 4,500 booklets/hour (A5-Finish, Portrait) Machine Dimensions SPF-200A 64″ (W) x 31.9″ (D) x 49.3″ (H) Machine Dimensions FC-200A 26.2″ (W) x 31.9″ (D) x 42.2″ (H) Issue rendering sage The Horizon SPF/FC-200A is a fully-automated combination stitcher/folder and face trimmer.

The Horizon SPF/FC-200A is a fully-automated combination stitcher/folder and face trimmer.

• Equipped with a user-friendly 10.4″ intelligent color touchscreen

• Advanced set-up automation

• Centralized control -

Horizon HOF-400 High-Speed Sheet Feeder

GM-HOR-HOF400

- Flexibility: The HOF-400 can be connected with Standard’s bookletmaking and saddlestitching solutions to process both digital and offset print through one efficient system.

- High speeds: Capable of handling the output of multiple printers, the HOF-400 can feed at a speeds up to 25,000 sheets per hour (A3 / 11” x 17”) or 35,000 sheets per hour (A4 SEF/ 8.5” x 11”).

Sheet Size Max 356 mm x 610 mm (14″ x 24″) Sheet Size Min 148 mm x 203 mm (6″ x 8″) Sheet Weight Range Normal: 52 to 157 gsm

Coated: 73 to 157 gsmProduction Speed Max 45,000 sheets per hour Issue rendering sage Fast, accurate, and flexible, the Horizon HOF-400 high speed offline feeder is ideal for digital booklet production. The system is compatible with functions such as cover feeding, sheet insert, variable page count, bleed trimming, and creasing for digital printing.

Fast, accurate, and flexible, the Horizon HOF-400 high speed offline feeder is ideal for digital booklet production. The system is compatible with functions such as cover feeding, sheet insert, variable page count, bleed trimming, and creasing for digital printing.

• Capable of handling the output of multiple printers

• up to 25,000 sheets per hour (A3 / 11” x 17”)

• up to 35,000 sheets per hour (A4 SEF/ 8.5” x 11”). -

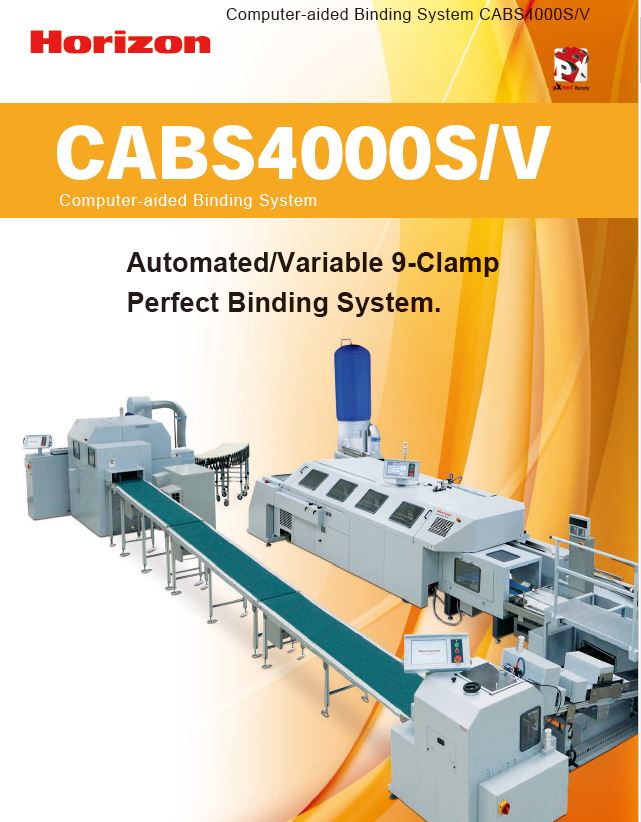

Horizon CABS 6000 Perfect Binding System

GM-HOR-CABS_6000The innovative Standard Horizon CABS 6000 perfect binding system is bringing new levels of automation to production bookbinding. The system includes the MG-600 Gatherer, SB-17 seventeen-clamp Perfect Binder, and a HT-110 Three-knife Trimmer. The system can produce up to 6,000 books/hour.

Key features: An in-line stacker for stand alone gathering, twin milling stations, automated in-line cover scoring, gauze feeding for hard cover book blocks, and advanced quality control features such as CCD cameras, digital caliper thickness detection, and weight checking.

Easy glue changeover: The CABS 6000 is equipped with quick-change EVA and PUR glue tanks that slide out on rails to a wheeled trolley. Operators can easily changeover from one binding style to another in about 5 minutes.

Cutting and trimming: The HT-110 Three-knife Trimmer produces trimmed books from 5.71” x 4.05” to 14.4” x 11.81”.

Book Size Max (Landscape) Off-line: 400 x 280 mm (15.74″ x 11.02″) / In-line: 385 x 275 mm (15.15″ x 10.82″) Book Size Min (Landscape) Off-line: 148 x 105 mm (5.83″ x 4.14″) / In-line: 148 x 105 mm (5.83″ x 4.14″) Book Size Max (Portrait) Off-line: 330 x 320 mm (12.99″ x 12.59″) / In-line: 250 x 320 mm (9.84″ x 12.59″) Book Size Min (Portrait) Off-line: 135 x 185 mm (5.32″ x 7.29″) / In-line: 135 x 185 mm (5.32″ x 7.29″) Book Thickness 2 to 50 mm (0.08″ to 2″) Cover Size Max 400 x 660 (15.74″ x 25.98″) Cover Size Min 135 x 220 mm (5.32″ x 8.67″) Cover Weight Range Normal: 81.2 to 303 gsm / Coated: 104.4 to 348 gsm Production Speed Max 6,000 books/hr Issue rendering sage The innovative Standard Horizon CABS 6000 perfect binding system is bringing new levels of automation to production bookbinding.

The innovative Standard Horizon CABS 6000 perfect binding system is bringing new levels of automation to production bookbinding.

• in-line stacker for stand alone gathering

• Twin milling stations

• Automated in-line cover scoring

• Advanced quality control features

-

Horizon SB-09 Perfect Binder

GM-HOR-SB09BENEFITS

- Highly accurate automated set-up is performed with simple and easy operation.

- Book production of up to 4,000 books per hour can be achieved.

- Both EVA hotmelt and PUR hotmelt are supported by using the interchangeable melt tanks.

- Two application rollers ensure superior penetration of hotmelt glue.

COVER FEEDING SECTION

- Cover feeder is available in two styles. One is a roller grip style feeder and the other is an optional rotary grip style feeder. Rotary grip style is designed to feed fl ap covers. Any double-feeds are detected by a supersonic sensor. Both feeders are bottom feeding and the cover can be loaded while running for continuous operation.

- Cover feeding / Scoring Section. The cover scoring wheels can create up to 4 score lines, and can be automatically set up according to the book thickness.

- Cover registerting/ Nipping Section. A superior nipping system experts powerful nipping pressure to create strong,durable binds with sharp spine corners. Automatic nipper height adjustment is available on SB09V/VF fully automated model.

- Delivery Section. The space effi cient vertical conveyor and the optional twisting conveyor LD-09T gently lay down and transport the fi nished book without damaging the spine especially for PUR bound books.

Book Size Max 400 x 280 mm (15.7″ x 11.0″) Book Size Min 148 x 105 mm (5.9″ x 4.2″) Book Thickness 1 to 45 mm (0.04″ to 1.77″) Cover Size Max 400 x 660 mm (15.7″ x 25.9″) Cover Size Min 135 x 220 mm (5.4″ x 8.7″) Cover Weight Range Normal: 82 to 302 gsm / Coated: 105 to 348 gsm Production Speed Max 4,000 books/hr Issue rendering sage The Horizon SB-09 nine-clamp perfect binder features automated operation, push-button simplicity, and high-quality production perfect binding.

The Horizon SB-09 nine-clamp perfect binder features automated operation, push-button simplicity, and high-quality production perfect binding.

• 10.4" intelligent touch screen control

• Automatic air suction cover feeder

• Handles wide range of materials

• High efficiency

• Up to 4,000 books/hr

• In-line trimmer -

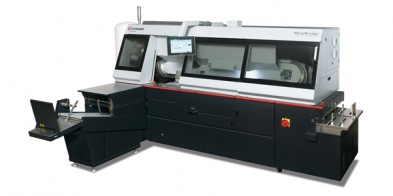

Horizon BQ-500 Perfect Binder

GM-HOR-BQ500The BQ-500 perfect binder is designed for increased book-of-one productivity, increased automation, and increased quality control over a wider range of substrates regardless of run length. The BQ-500 is the first perfect binder to come equipped with iCE LINK, Horizon’s new cloud-based JDF workflow and job-management tool. The system features an improved and easy-to-use 12.1” touchscreen for quick setup, an ergonomic design for efficient, operator-friendly operation, and an enhanced delivery system for thin books.

- Advanced automation: The BQ-500 features 21 automated sections in total, reducing setup and changeover time even when making fine variable thickness adjustments – all while ensuring higher quality books.

- Improved visual monitoring: A new, larger production monitoring screen and new, customizable LED lighting serve as a quick-look indicator of system readiness and status. Indicator lights can even be seen from across the production floor with the BQ-500’s light tower.

- Variable production: The BQ-500 is the most productive binder for book-of-one production in its class. In a variable range of +/-5mm, the BQ-500 can reach production speeds of up to 800 books per hour, almost double the productivity of other binders in this range.

- Expanded customization: The BQ-500 is designed to support a wide range of connectivity and enhancement options so that you can expand and tailor capabilities to match your unique needs.

- Clean spine preparation: Improved milling waste removal, a newly designed air flow, and an improved glue application system help ensure high-quality production.

- EVA and PUR: The BQ-500 features interchangeable EVA and PUR glue tanks with a new and improved tank removal process for cleaner and easier tank changeover.

- Gentle delivery: To prevent damage to more delicate books, the BQ-500 has reduced the book drop from 150mm to only 5mm. Books are then gently lowered to the delivery belt.

- iCE LINK: The BQ-500 is the first perfect binder to come equipped with iCE LINK, a cloud-based platform that can provide device monitoring, KPI analysis, PM schedule/alerts, JDF/JMF Workflow, scheduling, job creation, editing and more.

Book block Max: 12.59″ x 12.59″

Min: 5.70″ x 4.13″Cover size Max: 12.59″ x 26.37″

Min: 5.315″ x 8.859″Cover pile height 5.90″ Thickness Max: 2.55″

Min: 0.039″Cover thickness Coated: 104 to 348 gsm

Uncoated: 81.4 to 302 gsmProduction Speed(s) Up to 800 books/hr Issue rendering sage The BQ500 is designed to increase book-of-one productivity, increase automation, and quality control over a wider range of substrates.

The BQ500 is designed to increase book-of-one productivity, increase automation, and quality control over a wider range of substrates.

• Supports both EVA and PUR

• Produce high speed and high quality books without a skilled operator

• Up to 1,350 cycles per hour

• 12.1" user friendly touch screen -

BQ480 PERFECT BINDER (EVA)

GM-HOR-BQ480

The Horizon BQ-480 Perfect Binder features the quickest set-up and changeover for variable book production in its class, especially for book-of-one. Specially designed to meet the requirements of PUR book binding, the BQ-480 includes a gentle elevator delivery system with a mere 5mm drop, and also accommodates the lowest temperature setting for PUR glue. Interchangeable PUR and EVA glue tanks.

- PUR-friendly design: Specially designed to meet the requirements of PUR book binding, the BQ-480 includes a gentle elevator delivery system with a mere 5mm drop and accommodates the lowest temperature setting for PUR glue.

- Easy glue changeover: The BQ-480 also features interchangeable glue tanks to switch easily between PUR and EVA glue.

- Automated controls: The binder also offers advanced automation through a movable color touchscreen including adjustments for roller height, nipping height, and amount of side glue.

Issue rendering sage The Horizon BQ-480 Perfect Binder features the quickest set-up and changeover for variable book production in its class, especially for book-of-one. Interchangeable PUR and EVA glue tanks.

The Horizon BQ-480 Perfect Binder features the quickest set-up and changeover for variable book production in its class, especially for book-of-one. Interchangeable PUR and EVA glue tanks.

• Book Block Size: 5.71” x 4.14” – 12.59” x 12.59”

• Book Thickness: 0.04” to 2.56”

• Book of One Production-Max. 800 book/hr

• Cover Weight Range: Up to 348.9gsm

• Cycle Speed: 1,350 cycles/hr -

BQ-480 PERFECT BINDER (PUR)

GM-HOR-BQ480PUR

The Horizon BQ-480 Perfect Binder features the quickest set-up and changeover for variable book production in its class, especially for book-of-one. Specially designed to meet the requirements of PUR book binding, the BQ-480 includes a gentle elevator delivery system with a mere 5mm drop, and also accommodates the lowest temperature setting for PUR glue. Interchangeable PUR and EVA glue tanks.

• Book Block Size from 5.71” x 4.14” – 12.59” x 12.59”

• Book Thickness: 0.04” to 2.56”

• Book of One Production-Max. 800 book/hr

• Cover Weight Range: Up to 348.9gsm

• Cycle Speed: 1,350 cycles/hrIssue rendering sage The Horizon BQ-480 Perfect Binder features the quickest set-up and changeover for variable book production in its class, especially for book-of-one. Interchangeable PUR and EVA glue tanks.

The Horizon BQ-480 Perfect Binder features the quickest set-up and changeover for variable book production in its class, especially for book-of-one. Interchangeable PUR and EVA glue tanks.

• Book Block Size from 5.71” x 4.14” – 12.59” x 12.59”

• Book Thickness: 0.04” to 2.56”

• Book of One Production-Max. 800 book/hr

• Cover Weight Range: Up to 348.9gsm

• Cycle Speed: 1,350 cycles/hr