-

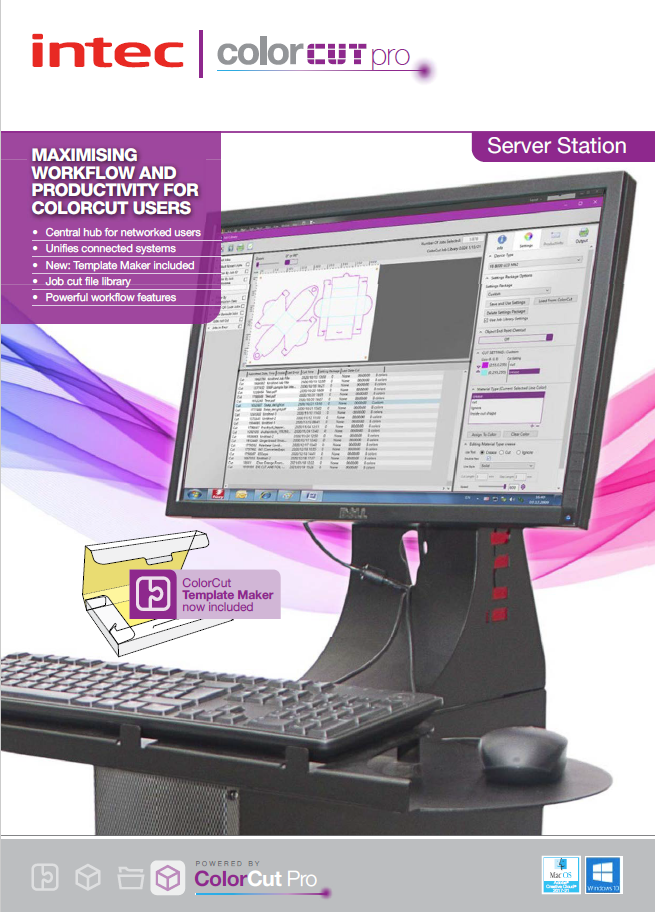

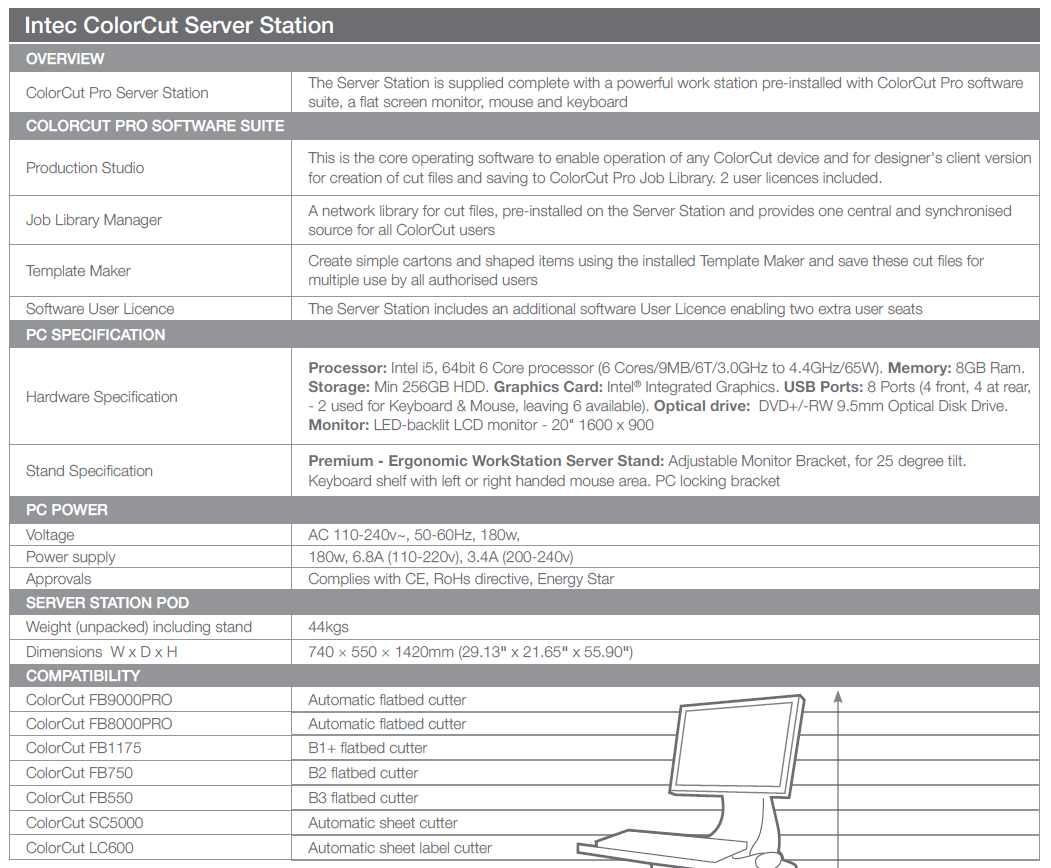

Morgana Intec ColorCut Server Station

GM-MSY-FBCCSTThe ColorCut Pro Server Station, an optional feature, enhances the efficiency of the production process and streamlines productivity.

Included in the Server Station is a well-designed workstation stand for ergonomic use, a powerful Windows© PC with 8 GB RAM, and the ColorCut Pro software package. This package encompasses a 20" LCD screen, a mouse, a keyboard, and a software user license for an additional 2 workstations.

Equipped with pre-installed Morgana ColorCut Pro software, the ColorCut Pro Server Station is capable of receiving jobs from both Mac and PC artwork computers within the same network. This creates an optimized ColorCut Job Library server, allowing for the autonomous production of cutting jobs without disrupting the workflow of graphic designers. Additionally, it features ColorCut Pro TemplateMaker for creating unlimited box designs and ColorCut Pro Job Library Manager for comprehensive control over cut files.

Includes:

- ergonomic workstation stand

- powerful Windows© PC with 8 GB RAM

- pre-installed ColorCut Pro software package (accepts jobs from Mac and PC)

- 20" LCD screen

- mouse

- keyboard

- software user licence for 2 additional working places

- Template Maker with ready-made jobs

- ColorCut Pro's Job Library Manager

US$2,499.00Issue rendering sageIntec ColorCut Server Stations are the central hub of ColorCut’s cutting ecosystem – connecting to each networked graphic designers’ system and integrating with the print/finishing room for seamless workflow automation.

US$2,499.00Issue rendering sageIntec ColorCut Server Stations are the central hub of ColorCut’s cutting ecosystem – connecting to each networked graphic designers’ system and integrating with the print/finishing room for seamless workflow automation.

• Production Studio 4 is the core operating software

• Template Maker enables designers to create simple cartons and shaped items

• Job Library Manager sophisticated job management -

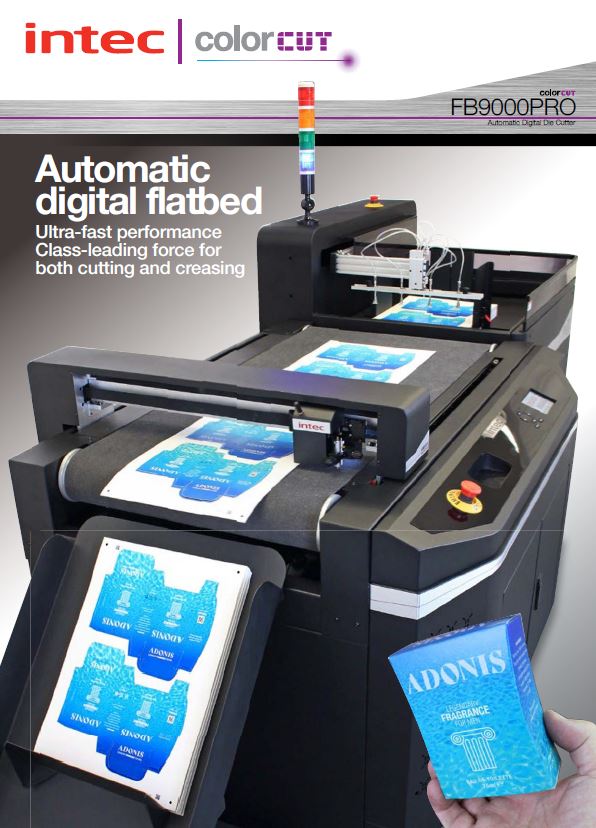

Morgana Intec ColorCut FB9000 Pro Auto Cutting System

GM-MSY-FB9000PRO_110KEY FEATURES & BENEFITS

The FB9000 is an advanced, fully automated digital die cutter delivers lightning speed performance, unparalleled media control and highly sophisticated, but user-friendly production functionality. This premium build system has a high capacity rapid auto feeder, paired with a large format continuous belt cutting table and media collection tray, which together offer synchronised auto-feed/load and eject for fully unattended operation and exceptional productivity. Tactile controls and immersive touch screen driven software provide an intuitive user experience ensuring you operate the FB9000PRO with the simplest daily operation and virtually no learning curve.

- Easy set-up and use. No need for dedicated operators/previous knowledge or specialised expertise. Unbox, connect and align feeder to cutter, plug in your PC via ethernet or USB and you’re ready to go!

- Cutter. The FB9000PRO’s dual tool head contains the latest Vision3 high resolution CCD camera, which reads a printed QR code to automatically retrieve the associated cutting file from the system and eliminating wasted time searching for jobs. Scanning the corner page SmartMarks also ensures precision registration of every sheet with its digital cut file.

- Feeder. Users can stack up to 2,000 sheets of printed media, even mixed batches for fully unattended operation, thanks to the QR code job identification. Each sheet is then automatically loaded on to the cutting belt using a highly effective pneumatic feed system.

- Software. Intec’s acclaimed ColorCut Pro software comes as standard. Features include: Remote Job Library, *SmartColors which allow different tasks and speed modes to be applied to different parts of the cut file and QR code reading which also allows the system to faultlessly identify and cut mixed jobs in the same session.

Digital Cutting

The FB9000PRO cutters use advanced digital contour cutting technology to follow artwork lines drawn in Adobe® Illustrator® or CorelDRAW® enabling you to cut and crease absolutely any shape, on demand, with no setup costs and no new software to learn.

Versatile Media Handling

Using the Auto Sheet Feeder, for unattended operation, the maximum media size is 480mm x 720mm. However, larger sheets can be cut in manual mode up to 550mm x 850mm. Designed to feed sheets in both portrait and landscape orientation, the system is equipped with an adjustable pick up head for wider sheets and larger media formats.

Dual Tool Heads

The separate cutting and creasing tools operate independently of each other, reducing operation time, improving productivity and providing the ability to specify different speed modes for ‘blended’ or multi speed cut and crease for accurate fast throughput. The cutting tool is supplied with a range of blades enabling a wide range of media tobe cut from labels up to 1,000 micron card stock. The creasing tool is double-ended, offering a choice of wide or narrow crease with an option to assign multi-creases within the ColorCut Pro software, to aid the creasing of difficult substrates.

Working Area (Manual Placement): 550mm x 850mm

Working Area (feeder): 480mm x 720mm

Width: 2850mm

Depth: 2095 mm

Height: 1035mm

Weight: 406.5kg

Max Speed: 1,200mm/s

Feeding Capacity: 25kg

Tooling: Twin head (1x cutter, 1x creaser)

Power supply

Cutter: 220-240V

Vacuum pump: 220-240V

Compressor: 220-240V

US$21,999.00Issue rendering sage The all NEW Morgana Intec FB9000 is an advanced, fully automated digital die cutter delivering lightning speed performance, unparalleled media control in a user-friendly format.

The all NEW Morgana Intec FB9000 is an advanced, fully automated digital die cutter delivering lightning speed performance, unparalleled media control in a user-friendly format.

• Easy set up and use

• Stacks 2,000 80gsm sheets

• Dual tool head contains highest resolution CCD camera

• ColorCut Pro software included -

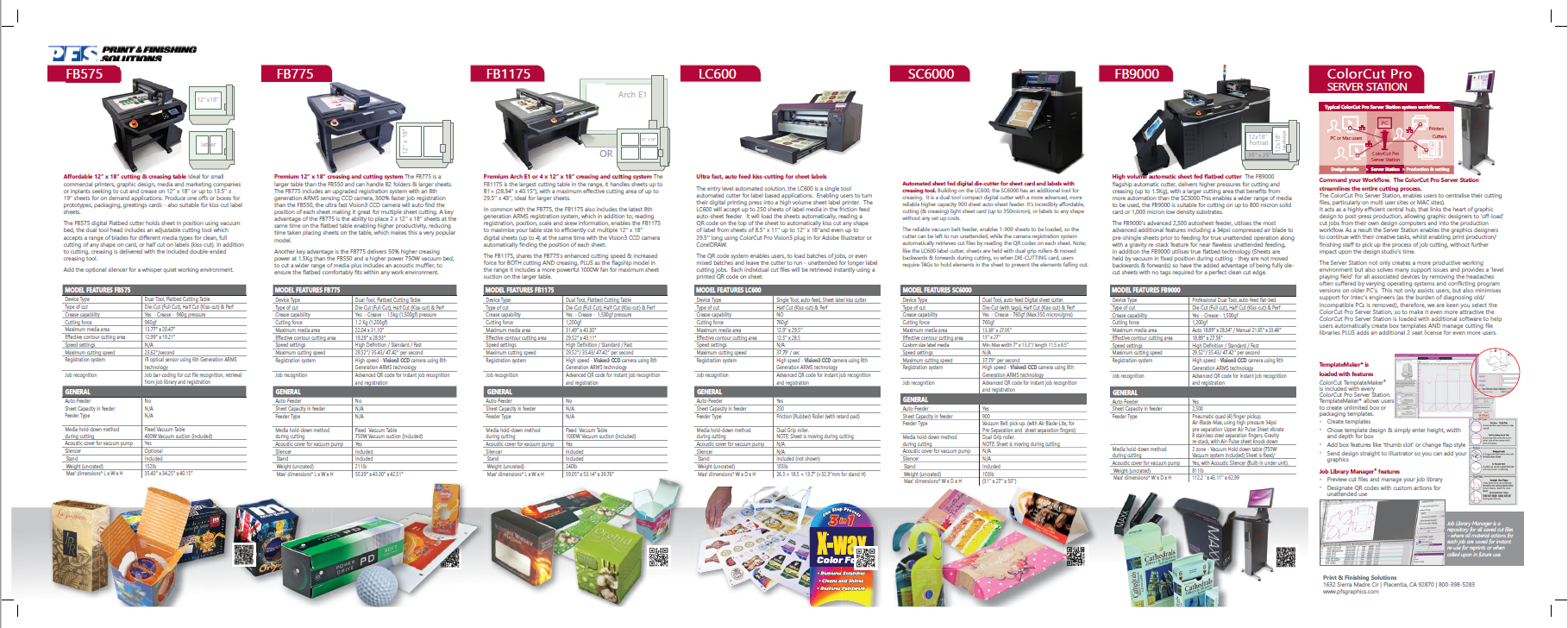

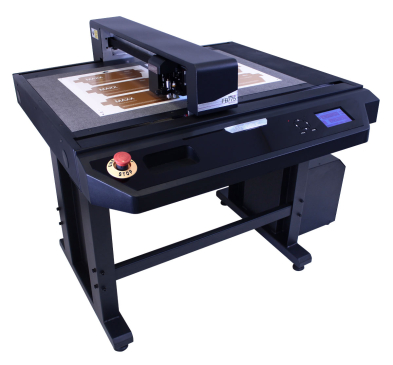

Morgana Intec ColorCut FB575 Digital Cutting System

GM-MSY-FB575_220The Morgana ColorCut FB575 Digital Cutting System is an affordable SRA3 cutting & creasing table ideal for small commercial printers, graphic design, media and marketing companies. Also, a solution for in-plants seeking to cut and crease on SRA3 or up to 350 x 488mm sheets for on demand applications, produce one-offs or boxes for prototypes, packaging, greetings cards – also suitable for kiss-cut label sheets.

The Morgana ColorCut FB575 Digital Cutting System’s dual tool head, includes an adjustable cutting tool which accepts a range of blades for different media types

The Morgana ColorCut FB575 Digital Cutting System has a flatbed cutter holding sheets in position using vacuum bed. The dual tool head includes an adjustable cutting tool which accepts a range of blades for different media types for clean, full cutting of any shape on card, or half cut on labels (kiss-cut). In addition to cutting, creasing is delivered with the included double-ended creasing tool. Add the optional silencer for a whisper quiet working environment.The ColorCut software also enables the system to perforate too. An IR optical sensor ensures accurate registration using 6th generation ARMS technology.

Job Bar-coding for cut file recognition, retrieval from job library and registration ensures that the right cutting path artwork is used for the individual printed sheet.

- No dies required – cut and crease any shape on demand

- Cuts card and films up to 450gsm / 600 micron

- Dual-tool head for same time cutting and creasing

- High productivity with cutting speeds up to 1 linear metre in 1.4 seconds!

- Optical Sensor driven to accurately follow vector cut/crease lines drawn in Adobe® Illustrator® & CorelDRAW®

- Vacuum suction media hold down table for even the smallest of items

- Complete with dedicated ColorCut Pro cutting & creasing software

Working Area (max): 12.99" x 19.21"

Width: 35.43"

Depth: 24.25"

Height: 40.15"

Weight: 152"

Max Speed: 23.62" per second

Power Supply: AC 110-220V 50/60Hz, 0.5A

Connectivity: USB (1 connection to PC is required)

Data Buffer: External PC

Tooling: Twin head (1 x cutter 1 x creaser)US$4,999.00Issue rendering sageThe Morgana ColorCut FB575 Digital Cutting System is an affordable SRA3 cutting & creasing table ideal for small commercial printers, graphic design, media and marketing companies. Also, a solution for in-plants seeking to cut and crease on SRA3 or up to 350 x 488mm sheets for on demand applications, produce one-offs or boxes for prototypes, packaging, greetings cards – also suitable for kiss-cut label sheets.

• No dies required – cut and crease any shape on demand

• Cuts card and films up to 450gsm / 600 micron

• Dual-tool head for same time cutting and creasing -

Morgana Intec ColorCut FB775 Flatbed Cutter

GM-MSY-FB775_220Morgana ColorCut FB775 B2+ Digital die cutter

The Morgana ColorCut FB775 digital die flatbed cutter is our mid range model. Incorporating a B2+ cutting table for large format sheet cutting, a QR code job retrieval and registration scanning system, which opens the associated cut file, and ensures your packaging, POS or labelling job is cut with outstanding speed and accuracy by the advanced, high-speed, servo motors that enable consistent and productive cutting. The enhanced dual-tool cutting head delivers up to 1,500gf pressure for creasing and 1,200gf for cutting – and cuts through paper/card up to 1,000micron, opening up new possibilities with its ground breaking design.The Morgana ColorCut FB775 B2+ Digital Die Cutter joining the highly successful digital die flatbed range.

The Morgana ColorCut FB775 is manufactured with premium components for high quality, reliability and class leading performance, reinforced with the aesthetic styling of the sweeping control panel dashboard, which includes a state-of-the-art 5″ immersive touch panel control.Morgana understands, ‘Time is Money’, so productivity was a core theme running through the design, therefore while the large B2+ cutting table is perfect for larger format work, we wanted users to be able to place multiple jobs on the table and let the cutter do the work for them. So, the sophisticated ColorCut Pro software (included) with the FB775 features a truly innovative ‘Productivity Mode’ enabling N-up sheets – even when mixed jobs are placed on the table – in this mode the FB775 will cut the first sheet, auto find and locate the next sheet, identify the cutting file required (if it is different), cut & crease and then move on to the next sheet.

This is the perfect partner for your business to deliver truly professional digital cutting, creasing and perforation, of any shape, on a range of materials up to 1,000 micron.

Intelligent job handling with the Morgana ColorCut FB775 B2+ Digital Die Cutter

The Morgana ColorCut FB775 digital cutter is an ideal mid-size cutter with greater productivity. Featuring the Vision3 CCD camera that reads QR codes printed on the job, instantly retrieving cut files for every job, and also reads SmartMarks to ensure accurate registration to your printed sheets. Other benefits include a live view of the cutting heads progress, within the ColorCut Pro Production Studio user interface.Supporting larger than B2 sheets, the cutting table can be maximised to accommodate multiple SRA3 and SRA4 sheets for continuous production, when using ‘Productivity Mode’ – where even mixed jobs can be read and cut in seamless perfection.

The range also includes the FB575, FB750 and FB1175. See an overview of the Flatbed Range page here.

- B2+ table takes SRA2 – or 2 x SRA3 and smaller

- No dies required – cut and crease any shape on demand

- Dual-tool head for same time cutting (1.2kgf) and creasing (1.5kgf)

- Blistering performance of up to 1,200mm/second

- Unparalleled accuracy using latest servo technology

- Cuts mixed jobs on table using QR coded auto job recognition to automatically retrieve associated cut files

- Cuts through up to 1,000 micron/800gsm paper/card, softboards and films to any shape

- Kiss-cuts perfect sheet labels of any shape

- CCD Video Camera driven to accurately follow vector cut/crease lines drawn in Adobe® Illustrator® & CorelDRAW®

- Vacuum suction media hold down table for even the smallest of items

- Effective cutting area 490 x 735mm

- Cut mixed job sheets for increased productivity on the bed, at the same time!

- Complete with dedicated ColorCut Pro cutting & creasing software, with Adobe® Illustrator® or CorelDRAW® plugins

Maximum media area: 800mm x 1100mm

Effective cutting area: 750mm x 1095mm

Width: 1350mm

Depth: 1550mm

Height: 1010mm

Weight: 246kg

Max Speed: 1,200mm/s

Max Cutting Depth: 1000micron / 800gsm

Data Buffer: PC / Mac

PC / Mac Tooling: Twin head (1 x cutter 1 x creaser)US$8,499.00Issue rendering sageThis premium FB775 digital cutter is an ideal mid-size cutter with greater productivity. Featuring the Vision3 CCD camera that reads QR codes printed on the job, instantly retrieving cut files for every job, and also reads SmartMarks to ensure accurate registration to your printed sheets. Other benefits include a live view of the cutting heads progress, within the ColorCut Pro Production Studio user interface.

• No dies required – cut and crease any shape on demand

• Dual-tool head for same time cutting (1.2kgf) and creasing (1.5kgf)

• Blistering performance of up to 1,200mm/second -

Morgana Intec ColorCut FB1175 Flatbed Cutter

GM-MSY-FB1175_UMThe Morgana ColorCut FB1175 – Perfect for light to medium run production of two and three dimensional items, the ColorCut series offers a range of machines to suit the cutting and creasing of virtually any form of print, from cardboard packaging for high-end products and protective cartons – to synthetic point-of-sale items and kiss-cut adhesive labels. The ability to digitally produce single items on demand, also makes the ColorCut perfect for prototyping.

ColorCut flatbed series defines a new industry standard. No matter whether you produce 2D point-of-sale and labels or 3D packaging and displays – ColorCut flatbed cutting tables will perform effortlessly, and on demand.

Cartons, packaging, point of sale & kiss cut labels -all with one system!

The flatbed come complete with a selection of cutting blades and mats to suit a wide range of materials being cut including lightweight papers, cards, label stock and synthetic substrates. Create stunning packaging with superb creasing and crisp cut lines/perforations on heavier-weight stocks for items such as luxury product packaging, gift boxes, utility packing and much more by using the supplied superior grey felt cutting mat and industrial circlip blades (included with every flatbed) making it suitable for use with heavier-weight materials. Perfect kiss-cut labels, interior and exterior point-of-sale, novelty greetings cards and vinyl decals can also be produced when used in conjunction with the provided self-healing cutting mat.Engineered for reliability

Designed in the UK, the ColorCut flatbed range has a pedigree of solid engineering, robust mechanical parts, the latest high-tech electronics and simplicity of use – all at an extremely affordable price point! Digital die cutting. Using advanced digital contour cutting technology, the flatbed tools follow artwork. cut and crease lines drawn in Adobe® Illustrator® or CorelDRAW® – no need to purchase and wait for traditional dies to be made.Key Features

Deliver on demand

Cuts a typical SRA3 sheet in just 30 – 60 seconds. This enables users to easily and affordably produce anything from as little as one or as many as 1,000 sheets per day.Vacuum hold down table

Sheets are held securely in place on either a green self-healing or superior grey felt cutting mat, by a vacuum produced by a powerful centrifugal air pump. Suction passes through the perforated hold down table and the mat, keeping sheets flat and secure.Job sensing

Perfect registration of the printed sheets to the desired cut line is guaranteed by the presence of an optical sensor or CCD camera, which reads page marks and barcode/ QR code (see software section), and enables the dual tool head to follow the path of drawn vector lines.Batch productivity

Multiple sheets can be placed on the cutting mat and with the control settings designated to ‘batch productivity’, ColorCut will proceed to work on each sheet in turn – thus speeding productivity even further!Dual tool cutting head

Delivering at least twice the pressure of other models in its class, the ColorCut flatbeds use a dual tool head where both tools operate independently from each other, for all functions, reducing operation time and improving productivity. The creasing tool is double-ended, offering a choice of wide or narrow crease, as required.Fingertip control

The intuitive touch screen control panel integrates with ColorCut Pro (see software section) and display’s easy to follow instructions, ensuring operators are able to respond effectively to system requirements.High power vacuum included

All Intec ColorCut flatbeds come with an extremely powerful centrifugal air pump which provides the power, to hold down printed sheets, onto the cutting table. An auto cut-off feature announces the end of each cut sheet. The pump is housed within an attractive, purpose made acoustic housing and supplied with an effective silencer*.Maximum media area: 800mm x 1100mm

Effective cutting area: 750mm x 1095mm

Width: 1350mm

Depth: 1550mm

Height: 1010mm

Weight: 246kg

Max Speed: 1,200mm/s

Max Cutting Depth: 1000micron / 800gsm

Data Buffer: PC / Mac

PC / Mac Tooling: Twin head (1 x cutter 1 x creaser)

Cutter: 200W, 3.0A , 110V 220V

Vacuum pump: 1000W, 110V / 16.5A (vacuum)US$12,999.00Issue rendering sage Perfect for light to medium run production of two and three dimensional items, the ColorCut series offers a range of machines to suit the cutting and creasing of virtually any form of print, from cardboard packaging for high-end products and protective cartons – to synthetic point-of-sale items and kiss-cut adhesive labels.

Perfect for light to medium run production of two and three dimensional items, the ColorCut series offers a range of machines to suit the cutting and creasing of virtually any form of print, from cardboard packaging for high-end products and protective cartons – to synthetic point-of-sale items and kiss-cut adhesive labels.

• Blistering performance of up to 1,200mm/second

• Cut size: 31.5" x 43"; 800gsm

• Cuts through up to 1,000 micron paper/card to any shape

• Kiss-cuts perfect sheet labels of any shape

-

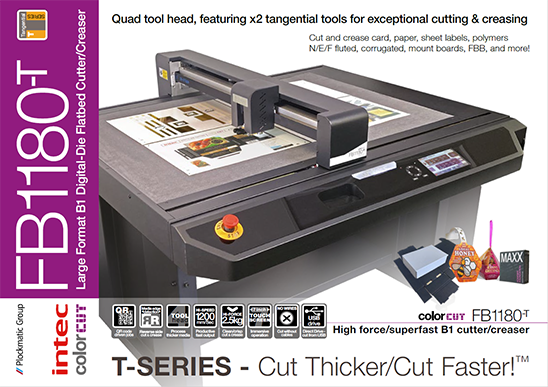

Morgana Intec ColorCut FB1180T Digital Flatbed Cutter

GM-MSY-FB1180T_UMThe Morgana ColorCut FB1180T is the latest addition in the FB1100 Series is designed to handle media 800 x 1100mm, introducing the ability to cut a wider range of media with its tangential cutting and creasing, with an effective cutting area of up to 680 x 1000mm.

Offering a QUAD TOOL HEAD with both drag/swivel and tangential capabilities the FB1180T has increased cutting and creasing forces. This offers outstanding results on FBB and SBB packaging boards and provides a wider range to include N, E and F fluted boards for packaging and point of sale applications.

The larger info-control panel provides a ‘No Wires’ working environment for remote locations; view and display your job to cut on the LCD screen, select by name or simply press scan to direct the cutter to auto-select the cut file.

Flat Bed Cutting Tables

Perfect for light to medium run production, the ColorCut series offers a range of machines to suit the cutting and creasing of virtually any form of print, from cardboard packaging for high-end products and protective cartons, to synthetic point-of-sale items and kiss-cut adhesive labels. The ability to digitally produce single items on demand, also makes the ColorCut perfect for prototyping.ColorCut flatbeds come complete with a selection of cutting blades and mats to suit a wide range of materials, including lightweight papers, cards, label stock and synthetic substrates.

Cuts a typical SRA3 sheet in just 30 – 60 seconds. This enables users to easily and affordably produce anything from one to 1,000 sheets per day.

Sheets are held securely in place by a vacuum air pump. Suction passes through the perforated hold down table and the mat, keeping sheets flat and secure.

- B1 table takes SRA1 – or 4 x SRA3 etc.

- Cutting force 2.5kg

- Creasing force 2.5kg

- Blistering performance of up to 1,200mm/second

- Unparalleled accuracy using latest servo technology

- Cuts mixed jobs on table using QR coded auto job recognition to automatically retrieve associated cut files

- Cuts through up to 1,000 micron paper/card to any shape and up to 3000 micron on selected fluted media

- Kiss-cuts perfect sheet labels of any shape

Max. cutting area: 720mm x 1020mm

Max. creasing area: 1280mm

Max. cut and crease area: 660 x 1020mm

Max. cutting depth: 3000 micron

Max. media area: 860 x 1180mm

Max. cutting speed: 1,200mm per second

Machine dimensions: 1550 x 1350 x 1010mmUS$17,999.00Issue rendering sagePerfect for light to medium run production, the ColorCut series offers a range of machines to suit the cutting and creasing of virtually any form of print, from cardboard packaging for high-end products and protective cartons, to synthetic point-of-sale items and kiss-cut adhesive labels.

• Blistering performance of up to 1,200mm/second

• Unparalleled accuracy using latest servo technology

• Cuts mixed jobs on table using QR coded auto job recognition to automatically retrieve associated cut files -

Morgana Rotary Die Cutter

GM-PLO-RDCOverview

The RDC is the ideal machine for the production of high volumes of boxes, labels and personalized items, such as business cards, greetings cards and postcards. It guarantees a professional quality and has a fast working speed. It is designed to meet the needs of today’s digital print applications, including short, medium and long run custom shaped products.

The RDC has an easy to use touch screen that has various setting adjustments for fine tuning the die location to the image, as well as adjustments for waste separation, job change and job storage. Accuracy of the cutting can be controlled by working from the lead edge or a printed registration mark of the sheet, side alignment also ensures that accuracy is repeated every time. Its intuitive settings enable you to produce up to 4,000 sheets / hour, enabling you to quickly meet any finishing requirement.

The RDC can be supplied with or without the sheet separator which can be added at a later date if required.

Cost Effective

The RDC is an incredibly efficient and cost-effective method of producing high volume cut items, meaning you can now truly offer a one stop for your customers. Increase the service you offer and cut unnecessary costs, whilst having the flexibility to choose your own lead times rather rely on a third party. With its fast production speed and simple to use setup, the RDC is the perfect investment for ‘on demand’ printing and finishing.

Accuracy at high Speed

With a very impressive running speed or 4,500 sheets per hour there is no other rotary die cutter on the market with such an impressive specification at such a competitive price. Using a top sheet air feed system, deep pile feeder and double sheet detector the RDC Rotary Die Cutter reduces the problems which can occur with today’s demanding digital outputs!

Maximum sheet size:14.5” x 20”

Minimum sheet size: 8.5” x 8.5”

Maximum die size: 15” x 20”

Minimum die size: 6.3” x 3.9”

Maximum die cut area: 14.2” x 18.6”

Minimum die cut area: 5.6” x 2.7”

Maximum paper thickness: 148lb

Minimum paper thickness: 78lb

Maximum speed: 4,500 sheets per hour

Feeder pile height: 15.7”

Dimensions: 111” x 31.5” x 42.1”

Power requirement: 220 Volts AC

Issue rendering sage The RDC is the ideal machine for the production of high volumes of boxes, labels and personalized items, such as business cards, greetings cards and postcards. Designed to meet today's digital print applications.

The RDC is the ideal machine for the production of high volumes of boxes, labels and personalized items, such as business cards, greetings cards and postcards. Designed to meet today's digital print applications.

• Easy to use touch screen

• Controlled Accuracy

• Produce 4,000 sheets/hr

• Supplied with or without sheet separator -

Morgana Intec Flatbed Blade 30° 3/pk

GM-MSY-FBBL30US$63.99Issue rendering sageIntec ColorCut flatbed blade yellow cutting knives 30° 1mm ø - for film, very soft material, and thin label material. No circlip. Compatible with all ColorCut models. -

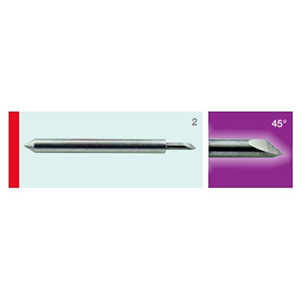

Morgana Intec Flatbed Blade 45° 3/pk

GM-MSY-FBBL45US$63.99Issue rendering sageIntec ColorCut flatbed blade red cutting knives 45° 1mm ø - typically for labels, stickers, and thin paper/card. No circlip. Compatible with all ColorCut models. -

Morgana Intec Flatbed Blade 60° 3/pk

GM-MSY-FBBL60US$63.99Issue rendering sageIntec ColorCut flatbed blade blue cutting knives 60° 1mm ø - for hard media. The sharply angled tip provides a sharper point edge. Suitable for penetrating harder media types. No circlip. Compatible with all ColorCut models.