-

LST Flatbed Cutter w/Computer & OptiScout

GM-CWT-08LST_0604RM

LST 1319 Digital Die Cutter. This is the perfect cost effective solution for a variety of finishing solutions. Kiss cut, die cut and crease all in one pass. CCD Camera registration for accurate sheet alignment. No cutting dies with automatic sheet fed production capable of handling 200 sheets in a continuous cycle.

• Cost effective digital die cut system

• Accuracy and speed with CCD vision camera system

• No cutting dies

• Automatic sheet fed production

-

The smallest of the CWT applicators, but still a very strong production machine built for working long shifts uninterrupted. This machine is perfect for things like yard signs, posters, political signs, and street signs. Comes completely assembled, just roll it out of the crate and into your shop!

• Self-healing cutting mat

• LED illuminated light table

• Roll holder for glide beam -

CWT 1428 Advantage Flatbed Laminating Table

GM-CWT-1428

The CWT1428 is an affordable, easy-to-use, high-production 4' x 8' work table for consistency, ease, and 85% quicker workflow applying transfer tape, as well as mounting and laminating graphics.

• Self-healing cutting mat

• LED illuminated light table

• Roll holder for glide beam -

The smallest of our premium applicators, but still a very strong production machine built for working long shifts uninterrupted. This is the machine for you if you want all the features, high production capacity, but do not need maximum table surface.

• Self-healing cutting mat

• Side pockets

• Roll holder for glide beam -

Premium Lamination Work Table

GM-CWT-1640Most popular model for commercial lamination. This is a very strong production machine built for working long shifts uninterrupted. Table surface will accommodate a large number of standard sheets and roller widths currently available on the market.

• Suitable for all types of installation work with self- adhesive materials.

• Workspace 3560x1560 mm 11ft. 8in. x 5ft. 1in.

• Bed size 4000x1600 mm 13ft.1in. x 5ft. 3in.

• Materials 0-70 mm/0-2,8in.

• Required air 6-8bar/87-116psi

• Capacity up to 140 m2/H 1500ft2/H -

Apollo XL-165 Substrate Cutter

GM-CWT-165The new Apollo XL can cut materials up to ¾” thick. It cuts

cleanly, accurately, without dust and noise. This is the most

affordable heavy-duty cutter available. Available in 4 sizes.

• 3x Quick change tool cartridges

• Integrated laser sight line

• Counter balance reduces operator fatigue

• Two Quick stops for added lateral support

• 5 year guarantee on all parts except bland and cutting wheels -

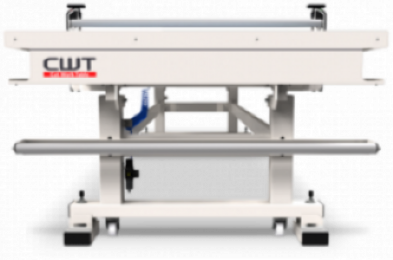

CWT Platinum 1736 Workstation

GM-CWT-1736A robust model with built in electric lift operation (ELO), 4.5" roller height, wide side pocets for flex face material, side measurements and knife grove for cutting.

• Table Size 5'5" x 10'9" -

CWT Platinum 1737 Workstation

GM-CWT-1737Complete workstation solution for application and cut works.

• Electronic pressure setting

• Heated roller 86F - 140F (optional)

• Remote controlled motorized horizontal drive (optional)

• Multiple height options

• Storage units

• Foldable roller

• Heavy duty