-

RMGT 10 Series - 1050LX

PM-RMG-1050LXThe RMGT 10 LX (wide stock range press) features a sheet transfer system that employs unique air management technology and a skeleton transfer cylinder that keeps the surface of the printed sheets from coming into contact with the cylinder. This prevents scratching and smearing, ensuring high printing quality. The lineup also includes models with coating units and curing units to handle high-grade high-gloss printing work. The RMGT 10 Series proudly boast the lowest overall cost of ownership for all large format packaging presses on the market today, yet still maintains the ability to run light weight label stocks.

Four Available Configurations include the LS, LX, TP (Tandem Perfector) and PF (Convertible Perfector) Models

Key Advantages

- Skeleton transfer cylinder keeps surface of printed sheets from coming into contact with cylinder

- Air chamber below transfer cylinder ensures stable sheet transfer for a wide range of sheet thicknesses

- Gripper height adjustment device adjusts the gripper pad height on the transfer cylinder according to the sheet thickness

- Remote controlled ink oscillating rollers dead point positioning (ink light and shade position remote control) and other ink adjustment devices specially for printing on heavy stock (optional)

- Automatic non-stop feeder and delivery shutter boosts productivity for continuous printing on heavy stock (option)

- Delta-type dampening system eliminates the need for hickey removal when printing on heavy stock (option)

- Chamber coater system maintains a consistent coating thickness regardless of printing speed (option)

- Parallel processing of printing procedure shortens make-ready time approximately 20-40% compared to previous presses.

Specifications (1050 LX)

- Maximum Printing Speed: 16,200 SPH

- Maximum Paper Size: 29.53” x 41.34” (750 x 1050mm)

- Minimum Paper Size: 14.17” x 21.26” (360 x 540mm)

- Maximum image Area: 29.13” x 41.34” (740 x 1050mm)

- Paper Thickness Range: .04 – 1.0mm (.0016 x .039”)

Issue rendering sage

The RMGT 10 Series is a high-throughput, full-size machine able to produce high-quality commercial products, as well as color-dominant short-run jobs with fast make-readies and consistent repeatability.

• Max. Paper Size: 29.53″ x 41.34″

• Max. Paper Thickness: 0.002″ - 0.031″

• Max. Printing Speed: 16,200 sph -

RMGT 970 8 color

PM-RMG-970”The new RMGT 9 of Al-size offset presses handles various print jobs with exceptionally high performance. Joining the proven 920 model with its extensive lineup, including convertible perfectors in up to ten colors, the 970 model is designed to accommodate an even wider range of jobs. This model is capable of running sheet sizes up to a maximum of 940 mm in width with a 930 mm wide printing image area and has successfully adopted many of the sophisticated functions found in the flagship RMGT 10. The high-speed separator, automatic nip checking function, and a host of other performance-enhancing features ensure that the RMGT 9 continues to deliver consistently high productivity.

“The entire industry suffered a loss when drupa was cancelled,” states Kian Hemmen, Director of Sales for Print & Finishing Solutions. “RMGT’s planned launch of the new 970 was a key step forward in our continuing leadership of the 8-UP market. The decision to launch now without the drupa push is a welcomed step and we can’t wait to see the RMGT 970 landing stateside. Growing our sheet size to the popular 25” x 38” format and adding RMGT’s new ASAP System will set the 970 apart from other players in this market segment. As we have since 2008, LED-UV curing will continue to play a major role in our customer’s success.

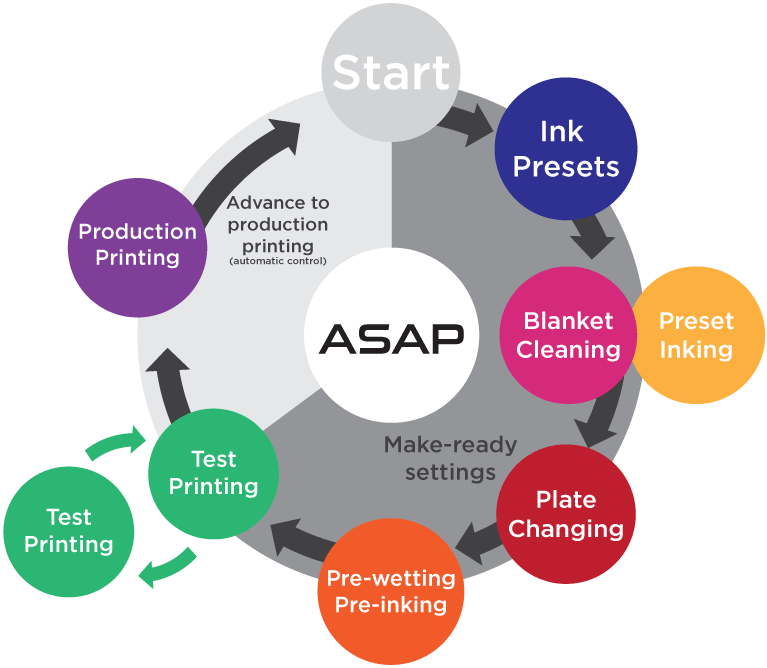

The ASAP System

Automated Smart Assist Printing increases press operating rates for continuous printing of short-run work

Smart Insta.Color technology has proven itself with fast makeready times for many years, and the release of the new ASAP system will allow RMGT customers to enjoy an entirely new level of automation and autonomous press operation in the 8 UP+ press format.With ASAP the pressman touches one button and the entire printing process—from ink and paper presetting, blanket and impression cleaning, and plate changing through verification of test printing, register adjustment, ink density adjustment, and full sheet inspection are all autonomously processed by the ASAP system without even pulling a sheet.

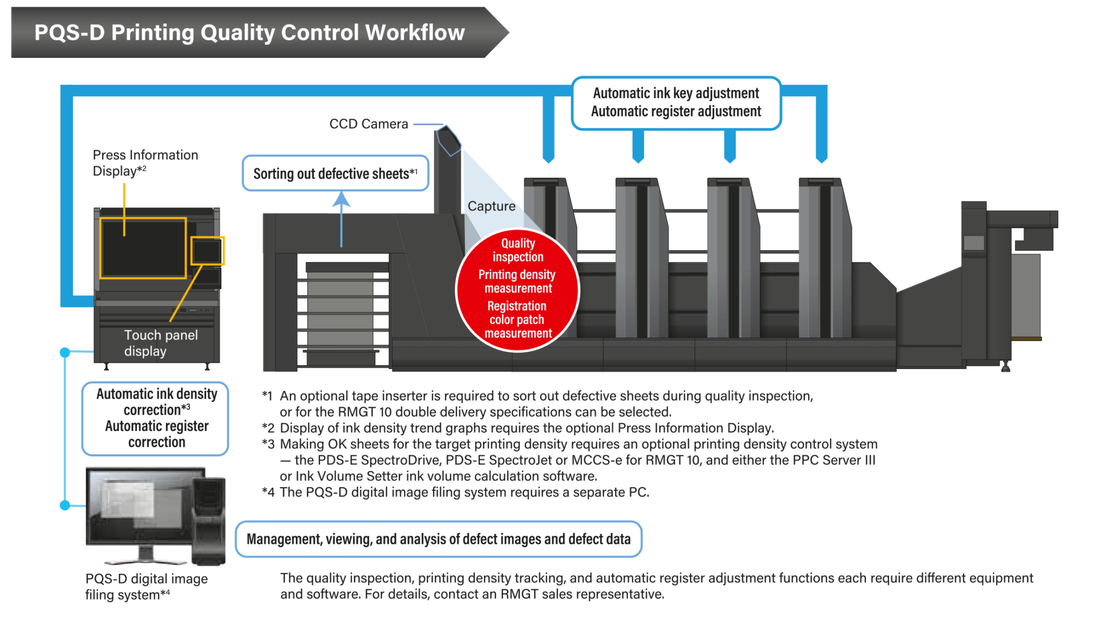

PQS-D (I+C+R) Print quality control system

Quality inspection function + Printing density function + Automatic register adjustment function

From commercial printing and very short run digital-like runs to packaging printing, RMGT’s PQS-D system uses a high-precision in-press CCD camera to inspect each printed sheet with superior reliability. The PQS-D eliminates the need to pull out sample sheets during the run and defective sheets are automatically sorted out, enhancing quality assurance and further automating printing.The multifunction PQS-D system lets you perform 3 key functions in-press with a single camera (per side of sheet). The scanning process can be archived to provide back up quality control data to a printer’s end user.

The beauty of the PQS-D (I+R+C) system is that the three functions detailed below are ALL processed at the same time, dramatically compressing the makeready time and allowing an RMGT pressman to focus on higher production.Issue rendering sage

RMGT’s recent launch of the new 970 was a key step forward in our continuing leadership of the 8-UP market. Growing our sheet size to the popular 25” x 38” format and adding RMGT’s new ASAP System will set the 970 apart from other players in this market segment.

-

RMGT 9 Series - 928PF

PM-RMG-928PLEDUVThe RMGT 9 series of A1-size offset presses enable high-performance 8-up printing of A4-size. Two model types are available, 940 models with a maximum sheet width of 940 mm, and 920 models with a maximum sheet width of 920 mm. Exceptional features such as a high printing speed of 16,200 S.P.H. and high printing quality make these presses ideal for printing companies seeking lower costs, high quality, and high productivity. In today’s highly competitive print market the RMGT 9 Series bridges the gap between short run digital printing with the capabilities for long run commercial as well as packaging applications.

Key Advantages

• Capable of 8-up printing of international A4 size or letter size

• Significantly lower printing plate costs, power consumption, and space requirements than a B1-size press (350 gsm with folding)

• Installation of one LED-UV (or UV) curing unit over the perfecting device and another over the delivery section enables one-pass instant-curing perfecting

• Inline coating system adds value to printed work

• Many of the same features as the flagship RMGT 10, including state-of-the-art sheet transfer technology and a function for quickly and easily checking the roller nip

• Newly developed press information display with a large 55-inch screen enables the operator to easily monitor printing quality and operating status in real time from the delivery section

• Feeder air presets accurately preset the air volume for the type of paper

• Parallel processing of blanket cleaning and preset inking (ink feeding) reduces make-ready time during job change over (for the press with Smart Make Ready function);Specifications (920 Model)

- Maximum Printing Speed: 16,200 SPH

- Maximum Paper Size: 25.20” x 36.22” (640 x 920mm)

- Minimum Paper Size: 11.42” x 16.14” (290 x 410mm)

- Maximum image Area: 24.21” x 35.43” (640 x 920mm)

- Paper Thickness Range: .04 – 0.6mm (.0016 x .024”)

Offset Tech Tools Part 1 from Socios on Vimeo.

Issue rendering sage

An 8-Up printing at a 6-Up price -The RMGT 9 Series is the dominant press in North-America with approximately 60 presses sold in recent years. No other press manufacturer offers this format with as much automation, flexible custom configurations, reliability, and acquisition cost.

• Max. Paper Size: 920 36.22″ x 25.20″

• Max. Paper Size: 940 37.01″ x 25.20″

• Max. Printing Speed: 17,100 sph -

RMGT 7 Series - 790ST-5

PM-RMG-756The 790 models can be configured according to customer needs, providing the optimum printing environment for increasing productivity and profitability. A highly reliable mechanism featuring the latest technologies and advanced automation devices, combined with a digital-controlled printing control system, ensures high-speed, high-quality printing. U/V and aqueous chambered anilox coating with full automation including all preset, plate loaders, closed loop spectrophotometry, ink volume setter software, double diameter impression and transfer cylinders and superior inking capabilities.

Key Advantages

· Easily handles 6 Up 8.5 x 11 Printed Pieces

· Double-diameter transfer cylinder for stable sheet transport

· Program inking, automatic plate changing system, various preset devices, and other automation systems significantly shorten make-ready

· Incorporating V-type feeder, the same high performance feeder as RMGT 10 series

· Fully automatic convertible perfecting device capable of one-pass perfecting

· Thick cardboard specification model handles sheet thicknesses up to 0.8 mm (option)

· An IR, UV, or LED-UV curing unit can be installed at the delivery section (option)

Specifications

- Maximum Printing Speed: 15,000 SPH

- Maximum Paper Size: 23.62” x 31.02” (600 x 788mm)

- Minimum Paper Size: 11.42” x 16.14” (290 x 410mm)

- Maximum image Area: 22.83” x 30.12” (580 x 765mm)

- Paper Thickness Range: .04 – 0.8mm (.0016 x .031”)

Issue rendering sage

The 7 Series provides unsurpassed print quality, reliability, and state-of-the-art automation with up to 31 point stock capabilities!

• B2-size multi-color offset press

• Max. paper size: 29.5 x 23.6”

• 31 X 23.6” can be fed -

RMGT 5 Series - 520GX

PM-RMG-524GXAThe RMGT 5 Series 520GX Model offers state-of-the-art technology for maximum printing quality and all-around performance, meeting a wide range of printing needs. The newly-developed GX series features a semi-automatic plate changer, pull side guide and impression pressure preset systems, a suction tape feeder board, automatic cleaning device, PCS-H printing control system, and program inking. Available option include ink volume setting software, printing density control system, fully automatic convertible perfecting device, and tower coater. The GX series can be configured for printing with UV inks; including LED, and UV coating applications.

The RMGT 520GX model features an array of automation and labor-saving systems plus other high-end technologies, delivering high printing speeds up to 15,000 SPH. From catalogs and heavy stock packaging to envelopes and postcards. The 5 Series has been a staple in the print industry since 1990

Key Advantages

· Wide Range of stock up to 24 Point

· "Semi-automatic plate changing device

· Excellent Ink Control and Water Control with Inverted C Roller Train

· Full Press Control from User Friendly Operation Stand

· Automation equal to Larger Format Presses

· Available with Coating Unit, Perfector and Award-Winning LED UV System

Specifications

- Maximum Printing Speed: 15,000 SPH

- Maximum Paper Size: 14.76” x 20.47” (375 x 520mm)

- Minimum Paper Size: 4.13” x 3.94” (105 x 100mm)

- Maximum image Area: 13.78” x 19.88” (350 x 505mm)

- Paper Thickness Range: .04 – 0.6 mm (.0016 x .024”)

Issue rendering sage

The 5 Series offset presses are specially designed for diverse, short-run and long-run printing of catalogs, high-quality art, packages, envelopes, and postcards with enhanced productivity and superior quality.

• A3-plus size 524GX 4-color/525GX

• 5-color/526GX 6-color presses

• Max. Paper Size: 20.47 x 14.76”

• Max. Printing Speed: 15,000 sph -

RMGT 340HA-4

PM-RMG-340HA4The RMGT A3-size Duplicator Presses have helped many printers grow into what they are today. Whether it is upgrading an outdated press or adding to the fleet, the RMGT 3 Series is still the best way to produce Black and White print as well as spot color. As the only press manufacturer still providing new smaller format presses the RMGT 3 Series is the go-to machine with decades of reliability. Parts and Service are readily available.

The RMGT 340HA-4 A3-size vertical offset 4-color printing machine developed to meet market needs such as colorization and digitization. It is highly effective for printing short run multicolor production such as postcards, leaflets, direct-mail advertisements, and envelopes.

Key Advantages

- SPC Semi-automatic Plate Changing system

- Sheet size change button

- RP520-220F high precision register punch

- PCS-F print control system

- Diagonal image adjustment paper feed cylinder and dial-type image adjustment device

- Satellite V-shaped 5-cylinder system

- SuperDampener

- Delivery side centralized operation panel

- Fast and efficient production of small lot printing

- Compact and space-saving

Specifications

- Maximum Printing Speed: 10,000 SPH

- Maximum Paper Size: 13.38” x 17.71” (450 x 340mm)

- Minimum Paper Size: 3.54” x 5.12” (130 x 90mm)

- Maximum image Area: 13” x 17.25” (438 x 330mm)

- Paper Thickness Range: .04 – 0.3 mm

Issue rendering sage

The RMGT 340HA-4 A3-size vertical offset 4-color printing machine developed to meet market needs such as colorization and digitization. It is highly effective for printing short run multicolor production such as postcards, leaflets, direct-mail advertisements, and envelopes.

• Maximum Printing Speed: 10,000 SPH

• Maximum Paper Size: 13.38” x 17.71”

• Minimum Paper Size: 3.54” x 5.12”

• Maximum image Area: 13” x 17.25”

• Paper Thickness Range: .04 – 0.3 mm -

RMGT 340HA-2

PM-RMG-340HA2The RMGT A3-size Duplicator Presses have helped many printers grow into what they are today. Whether it is upgrading an outdated press or adding to the fleet, the RMGT 3 Series is still the best way to produce Black and White print as well as spot color. As the only press manufacturer still providing new smaller format presses the RMGT 3 Series is the go-to machine with decades of reliability. Parts and Service are readily available.

The RMGT 340HA-2 / 340C-2 A3 Portrait Format 2-color Offset Presses feature a variety of functions for faster, easier printing. The compact design and economical multi-color printing capability are ideal for short-run color printing work such as postcards, leaflets, direct-mail advertisements, and envelopes.

Key Advantages

- Adopted satellite type cylinder arrangement consisting of double diameter impression cylinder and double diameter, triple diameter transfer cylinder

- "Semi-automatic plate changing device SPC" (340HA-2 / 340CA-2) that can perform plate changing work accurately in a short time

- "Super dampener" (340HA-2), a continuous water supply / humidification device that forms an optimal water film on the plate surface from the start-up

- "Crestline continuous water supply device" (340CA-2 / 340C-2) for easy water volume adjustment

- Diagonal image adjustment by the feed cylinder and dial type image position adjustment

- A lever-type ink fountain that allows you to easily make fine adjustments in color matching *

- "Print management system PCS-F" (option) consisting of a split-type ink fountain and an operation stand for remote control of ink keys

Specifications

- Maximum Printing Speed: 10,000 SPH

- Maximum Paper Size: 13.38” x 17.71” (450 x 340mm)

- Minimum Paper Size: 3.54” x 5.12” (130 x 90mm)

- Maximum image Area: 13” x 17.25” (438 x 330mm)

- Paper Thickness Range: .04 – 0.3 mm

Issue rendering sage

The RMGT 340HA-2 / 340C-2 A3 Portrait Format 2-color Offset Presses feature a variety of functions for faster, easier printing. The compact design and economical multi-color printing capability are ideal for short-run color printing work.

• Maximum Printing Speed: 10,000 SPH

• Maximum Paper Size: 13.38” x 17.71”

• Minimum Paper Size: 3.54” x 5.12”

• Maximum image Area: 13” x 17.25”

• Paper Thickness Range: .04 – 0.3 mm

-

RMGT 340CR-1

PM-RMG-340CR_1The RMGT A3-size Duplicator Presses have helped many printers grow into what they are today. Whether it is upgrading an outdated press or adding to the fleet, the RMGT 3 Series is still the best way to produce Black and White print as well as spot color. As the only press manufacturer still providing new smaller format presses the RMGT 3 Series is the go-to machine with decades of reliability. Parts and Service are readily available.

With a robust inking system with 16 rollers, including 3 inking rollers, prints photos, solids and screens in high quality. The proprietary registration device and an optional second color head enable the RMGT 340CR-1 to meet the need for multi-color printing.

KEY Advantages

- "Original second color head" (option) that economically meets the needs for simple colorization

- Crestline dampening system

- Single lever operation from humidification and inking to plate, imaging, paper feeding and printing

- Operator-friendly controls

- A "needle registration device" that reliably positions the paper on the feeder board

- "Straight edge plate clamp with register pin" that firmly fixes the grip of the plate

Issue rendering sage

With a robust inking system with 16 rollers, including 3 inking rollers, prints photos, solids and screens in high quality. The proprietary registration device and an optional second color head enable the RMGT 340CR-1 to meet the need for multi-color printing.

• Maximum Printing Speed: 10,000 SPH

• Maximum Paper Size: 13.38” x 17.71”

• Minimum Paper Size: 3.54” x 5.12”

• Maximum image Area: 13” x 17.25”

• Paper Thickness Range: .04 – 0.3 mm

-

RMGT 340PCX-2

PM-RMG-3200PCXThe RMGT A3-size Duplicator Presses have helped many printers grow into what they are today. Whether it is upgrading an outdated press or adding to the fleet, the RMGT 3 Series is still the best way to produce Black and White print as well as spot color. As the only press manufacturer still providing new smaller format presses the RMGT 3 Series is the go-to machine with decades of reliability. Parts and Service are readily available.

The most efficient way of printing 1/1 documents, the RMGT 340PCX-2 A3 Automatic Perfector boosts productivity. The 340PCX-2 has an array of automation and labor-saving functions embodying RMGT’s wealth of small press expertise. The blanket-to-blanket type automatic perfector features lever-less printing and controls at the delivery section to reduce operator burden and make operation easier. Ideal press for In Plant operations to produce up to 20,000 11 x 17 impressions per hour.

Key Advantages

- Automatic continuous printing

- Crestline dampening system

- Easy push-button operation

- Stable blanket-to-blanket perfecting and direct chain delivery

- Reliable sheet feed and delivery

- Pre-piling with large pile capacities

Specifications

- Maximum Printing Speed: 10,000 SPH

- Maximum Paper Size: 13.38” x 17.71” (450 x 340mm)

- Minimum Paper Size: 3.54” x 5.12” (130 x 90mm)

- Maximum image Area: 12.49” x 17.25” (438 x 317mm)

- Paper Thickness Range: .04 – 0.3 mm

Issue rendering sage

The most efficient way of printing 1/1 documents, the RMGT 340PCX-2 A3 Automatic Perfector boosts productivity. The 340PCX-2 has an array of automation and labor-saving functions embodying RMGT’s wealth of small press expertise.

• Maximum Printing Speed: 10,000 SPH

• Maximum Paper Size: 13.38” x 17.71”

• Minimum Paper Size: 3.54” x 5.12”

• Maximum image Area: 12.49” x 17.25”

• Paper Thickness Range: .04 – 0.3 mm -

RMGT 340CCD-1

PM-RMG-340CCDThe RMGT A3-size Duplicator Presses have helped many printers grow into what they are today. Whether it is upgrading an outdated press or adding to the fleet, the RMGT 3 Series is still the best way to produce Black and White print as well as spot color. As the only press manufacturer still providing new smaller format presses the RMGT 3 Series is the go-to machine with decades of reliability. Parts and Service are readily available.

A3-size vertical single-color printing machine developed with the operator's operability and productivity in mind. A crest line continuous water supply system is adopted that makes it easy to adjust the water volume and supply a stable dampening water. It can handle small lots flexibly and can handle a wide variety of small lots.

KEY Advantages

- Lower Cost of manufacturing vs. Digital Devices

- Crestline dampening system

- High reliability backed by proven technology

- Operator-friendly controls

- Centrally located switches and other controls plus an easy-to-use swiveling operation panel

- Dial-type vertical image position adjustment for easy and accurate image position adjustment

- Master guides to ensure accurate positioning of paper master

Specifications

- Maximum Printing Speed: 10,000 SPH

- Maximum Paper Size: 13.38” x 17.71” (450 x 340mm)

- Minimum Paper Size: 3.54” x 5.12” (130 x 90mm)

- Maximum image Area: 13” x 17.25” (438 x 330mm)

- Paper Thickness Range: .04 – 0.3 mm

Issue rendering sage

A3-size vertical single-color printing machine developed with the operator's operability and productivity in mind. It can handle small lots flexibly and can handle a wide variety of small lots.

• Maximum Printing Speed: 10,000 SPH

• Maximum Paper Size: 13.38” x 17.71”

• Minimum Paper Size: 3.54” x 5.12”

• Maximum image Area: 13” x 17.25”

• Paper Thickness Range: .04 – 0.3 mm