-

GFP 865DH-4RS Dual Heat Laminator

GM-GFP-865DH_4RSFor finishing professionals who need versatility, quality, and economy in one machine, the Gfp 865DH-4RS delivers. Turn out thermal encapsulation with low melt films (1.5-10mil), PSA lamination, and mounting jobs quickly and easily. Spend less time on set-ups and changeovers with swing-out quick-grip supply shafts. Two front rewind shafts allow thermal encapsulation of prints from a roll.

• Labor saving swing-out supply shafts

• Drop-in Quick-Grip rewind shafts

• Photoelectric eye for operator safety

• Independent top and bottom heaters

• Web clutch adjustment for output quality

• Includes rear rewind with rotary slitters

• Swing-up feed table and 38" output heightLaminating Width: 65"

Roller Diameter: 5"

Roller Gap: 1"

Main Rollers: Silicone

Supply roll diameter (Max): 16" bottom, 8" top

Film shafts: 3" aluminum quick-grip

Rear Rewind with rotary slitters: Included

Max. temperature: 266° F

Heat method: Quartz heater

Film thickness: 1.5 - 10mil

Laminating speed: 0-13 ft/min

Pressure adjustment: Dual hand wheels

Roller heating: Top & bottom

Power Supply: 240v 60HZ Single phase 24A

Power Consumption: Max. 5760W

Dimensions: 87" x 34" x 49"

Net Weight w/ stand: 846 lbs.Issue rendering sage

For finishing professionals who need versatility, quality, and economy in one machine, the Gfp 865DH-4RS delivers.

• Labor saving swing-out supply shafts

• Drop-in quick-grip rewind shafts

• Photoelectric eye for operator safety -

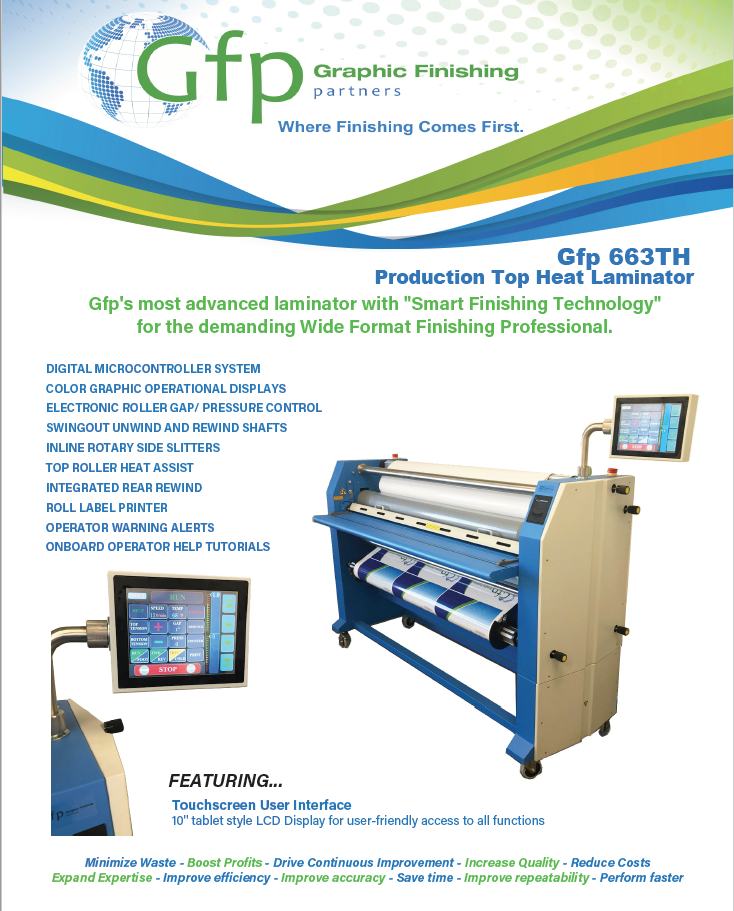

GFP 663TH Production Top Heat Laminator

GM-GFP-663THMicroprocessor technology has expanded capabilities for Wide Format Finishing Professionals by increasing the

efficiency, accuracy and reliability of finishing equipment. But that's not all. Now operators can program, monitor

and display all machine functions and view operator tutorials through a powerful digital touchscreen Microcontroller.

As a result, the Gfp 663TH expands operator expertise, productivity and accuracy providing consistent

quality output and fewer production errors.

• Digital microcontroller system

• Color graphic operational displays

• Electronic roller gap / pressure control

• Swingout unwind and rewind shafts

• Inline rotary side slitters

• Top roller heat assist

• Integrated rear rewind

• Roll label printer

• Operator warning alerts

• Onboard operator help tutorialsLaminating Width: 63"

Roller Diameter: 5"

Roller Gap: 1"

Main Rollers: Silicone

Supply Roll Diameter (Max): 8" OD (top); 16" OD (bottom)

Supply Shafts: 2 Swing-out

Rear Rewind: Included

Rear Inline Slitters: Rotary Design

Maximum temperature: 140° F

Heat method: Metal Alloy heater

Film Core Size: 3"

Laminating Speed: 0-20 ft/min

Pressure Adjustment: Electric Servo Motor

Output Height: 38"

Foot Pedal: Included

Stand with casters: Included

Power Supply: 120v 12A

Power Consumption: 1440W

Net weight with stand: 675 lbs.

Dimensions: 83" x 30.7" x 63"Issue rendering sage

Gfp's most advanced laminator with "Smart Finishing Technology" for the demanding wide format finishing professional.

• Digital microcontroller system

• Color graphic operational displays

• Electronic roller gap / pressure control -

GFP 563TH-4RS Top Heat Laminator w/Swing Out Shafts

GM-GFP-563TH_4RSWhat's the best way to make your production even better? Shorten film loading time? Make fewer film changes? Increase throughput speed? The 563TH-RS does all that and more.

• Swing-out quick-grip supply shafts

• Drop-in quick-grip rewind shafts

• Photoelectric eye for safety

• Includes rear rewind with Rotary Slitters

• Swing-up feed table & 38" output height

• Metal Alloy heater reduces breakage

• 4.4" diameter rollers

• Roller gap measurement scaleLaminating Width: 63"

Roller Diameter: 4.5"

Roller Gap: 1"

Rear Rewind with Slitters: Included

Maximum temperature: 140° F

Laminating Speed: 0-20ft/min

Pressure Adjustment: Hand Wheel

Heat method: Metal Alloy heater

Max. roll diameter: 8" OD (top); 16" OD (bottom)

Supply Shafts: 2 Swing-out

Tension Adjustment: Single knob

Power Supply: 110v 12A

Power Consumption: 1320W

Foot Pedal: Included

Stand with casters: Included

Dimensions: 87" x 26.5" x 52.5"

Net Weight w/ stand: 491 lbs.Issue rendering sage

What's the best way to make your production even better? Shorten film loading time? Make fewer film changes? Increase throughput speed? The 563TH-RS does all that and more.

• Swing-out quick-grip supply shafts

• Drop-in quick-grip rewind shafts

• Photoelectric eye for safety -

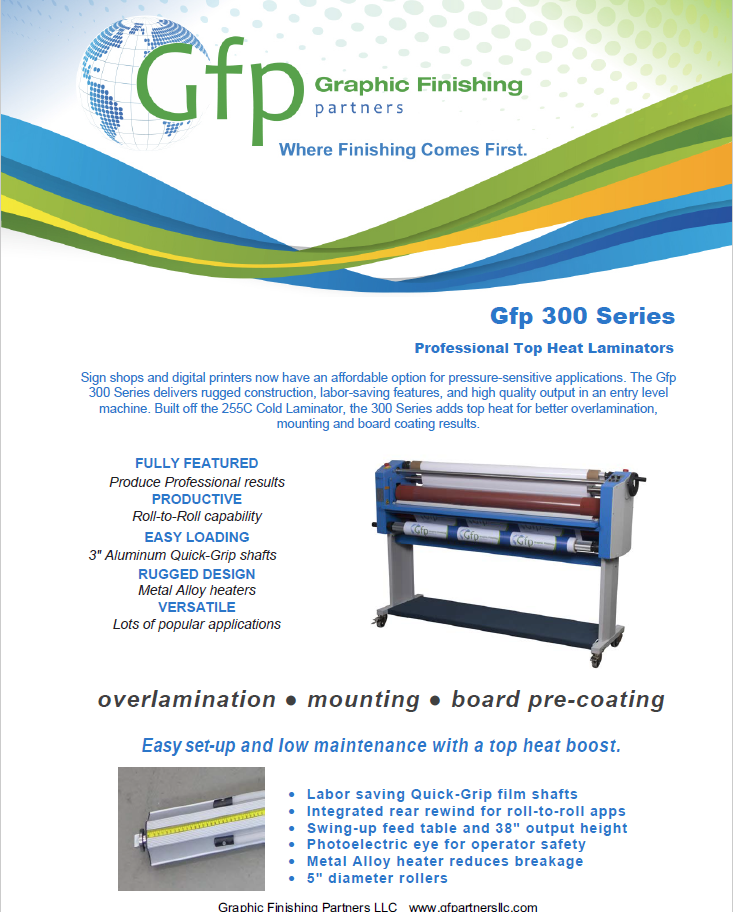

GFP 300 Series 55" Top Heat Laminator

GM-GFP-355THSign shops and digital printers now have an affordable option for pressure-sensitive applications. The Gfp 300 series delivers rugged construction, labor-saving features, and high quality output in an entry level machine. Built off the 255C Cold Laminator, the 300 series adds top heat for better overlamination, mounting and board coating results.

• Labor saving quick-grip film shafts

• Integrated rear rewind for roll-to-roll apps

• Swing-up feed table and 38" output height

• Photoelectric eye for operator safety

• Metal Alloy heater reduces breakage

• 5" diameter rollersLaminating Width: 55"(model 355TH) / 63" (363TH)

Roller Diameter: 5"

Roller Gap: 1"

Main Rollers: Rubber

Rear Rewind: Integrated

Maximum temperature: 140° F

Laminating Speed (feet/minute): 20ft/min

Unwinds: Top/Bottom

Linear Rewind: Chain Drive

Pressure Adjustment: Hand Wheel

Tension Adjustment: Single knob

Heat method: Metal Alloy heater

Max. roll diameter: 6" OD

Power Supply: 120v 11A/120v 12A

Power Consumption: 1320W/1440W

Foot Pedal: Included

Stand with casters: Included

Net Weight w/ stand: 321 lbs.

Dimensions (355TH): 7" x 23.5" x 48.5"

Dimensions (363TH): 80" x 23" x 48"Issue rendering sage

The Gfp 300 series delivers rugged construction, labor-saving features, and high quality output in an entry level machine.

• Labor saving quick-grip film shafts

• Integrated rear rewind for roll-to-roll apps

• Swing-up feed table and 38" output height -

GFP 200 Series 63" Cold Laminator

GM-GFP-263CThe Gfp 200 Series laminators are the affordable alternative to time-consuming hand finishing with rollers and squeegees. Now even the smallest shops can compete for bigger jobs with confidence. The 200 Series will shorten production time, increase profitability and produce consistently professional results.

• Labor saving Quick-Grip aluminum film shafts for easy loading

• Variable roller gap to 1"

• Single pressure adjustment

• 4.5" diameter rollers

• Chain drive rewind

• 38" output heightLaminating Width: 63"

Roller Diameter: 4.5"

Max Speed: 13ft/min

Main Rollers: Rubber

Roller Gap: 1"

Pressure/Gap Adjustment: Infinite

Pressure/Gap Mechanism: Hand Wheel

Unwinds: Top/Bottom

Liner Rewind: Chain Drive

Supply Shaft: 3" Quick-Grip

Tension Adjustment: Single knob

Max. roll diameter: 8" OD

Power Supply: 110v 0.4A

Power Consumption: 44W

Foot Pedal: Included

Stand with casters: Included

Net Weight w/ stand: 322 lbs.

Dimensions: 80" x 24" x 55"Issue rendering sage

The Gfp 200 Series laminators are the affordable alternative to time-consuming hand finishing with rollers and squeegees. Now even the smallest shops can compete for bigger jobs with confidence. The 200 Series will shorten production time, increase profitability and produce consistently professional results.

• Labor-saving quick-grip aluminum film shafts

• Variable roller gap to 1"

• Single pressure adjustment -

GFP 200 Series 55" Cold Laminator

GM-GFP-255CThe Gfp 200 Series laminators are the affordable alternative to time-consuming hand finishing with rollers and squeegees. Now even the smallest shops can compete for bigger jobs with confidence. The 200 Series will shorten production time, increase profitability and produce consistently professional results.

• Labor saving Quick-Grip aluminum film shafts for easy loading

• Variable roller gap to 1"

• Single pressure adjustment

• 4.5" diameter rollers

• Chain drive rewind

• 38" output heightLaminating Width: 55"

Roller Diameter: 4.5"

Max Speed: 13ft/min

Main Rollers: Rubber

Roller Gap: 1"

Pressure/Gap Adjustment: Infinite

Pressure/Gap Mechanism: Hand Wheel

Unwinds: Top/Bottom

Liner Rewind: Chain Drive

Supply Shaft: 3" Quick-Grip

Tension Adjustment: Single knob

Max. roll diameter: 8" OD

Power Supply: 110v 0.4A

Power Consumption: 44W

Foot Pedal: Included

Stand with casters: Included

Net Weight w/ stand: 257 lbs.

Dimensions: 73" x 24" x 55"Issue rendering sage

The Gfp 200 Series laminators are the affordable alternative to time-consuming hand finishing with rollers and squeegees. Now even the smallest shops can compete for bigger jobs with confidence. The 200 Series will shorten production time, increase profitability and produce consistently professional results.

• Labor-saving quick-grip aluminum film shafts

• Variable roller gap to 1"

• Single pressure adjustment -

GFP FT48 60" Finishing Table

GM-GFP-FT48The FT48 turns any roll laminator into a sign making, flatbed applicator for mounting or laminating

rigid substrates and printed sheets by providing a faster, easier one-step roll application process.

It combines a 60” W x 48” D roller ball transfer table with a cutting surface, both in one space

saving accessory.• Lower cost

• Dual functionality

• Faster workflow

• Lightweight strength and durability

• Simple set-up/operation

• Comfortable 38" table height

• Two-sided work surface

• Space-saving portabilityThe Transfer table side features 4 rows of transfer balls for easy positioning of images and precise

alignment. It includes a full-length 48" side guide and printed alignment guides for straight feeding

of standard board widths. Roll the table away and you have all the advantages of a roll laminator.The Cutting table side allows easy alignment of graphics that need to be trimmed. The surface is

thick, durable 180-gauge, 3/16” translucent Polyethylene (LDPE). Its seamless translucent white,

non-glare surface can be cut with rotary cutters and utility knives repeatedly without leaving marks.

This self-healing surface means more accurate cuts and less blade wear.Outer dimensions when folded: 70.5" W x 32" D x 61" H

Outer dimensions when operational: 70.5" W x 49" D x 38” H

Table surface dimensions: 61" W x 48" L x 2” H

Net weight: 148 lbs.

Caster height adjustment range: 3/8”

Working table height: 38"Issue rendering sage

The FT48 turns any roll laminator into a sign making, flatbed applicator for mounting or laminating

rigid substrates and printed sheets by providing a faster, easier one-step roll application process.

• Simple set-up/operation

• Comfortable 38" table height

• Two-sided work surface