-

ADDITIONAL FEATURES:

6,000 sheets per hour 1 number per head per sheet 1 or 2 Numbering Heads Tabletop model with automatic feed Crash numbering up to 10 part carbonless Feed sets unglued or glued side Create snap sets while numbering Heads rotate & lock throughout 360 degrees Perforating options 2,4,6,8,12,16 teeth per inch (TPI), 42,50 and 72 Microperf TPI Accurate .010″ register Ability to control depth of Perf/Score/Slit Microprocessor controlled with forward and backward stepping for easy programming Specifications: Length 44″ (1.12m)

Width 27″ (0.69m)

Height 16″ (.26m)

Weight 106lbs (48kg)Speed: 6,000 sheets/sets per hour (11″ x 8.5″ – A4) Numbering: Solenoid operated drive of one or two numbering heads – 1 drive unit with 6 wheel gothic style reverse numbering head standard – Operational through 360º, lockable at any rotation – Consecutive, 2x, 3x, 4x actions – Standard heads drop 2 wheels, customization available – Optional condensed wheel style to 8 digits – Nº and letter prefixing available – Inked by reservoir pad, red and black supplied Accessories: One accessory holder supplied standard – 12 tooth per inch perf blade and scoring blade supplied standard – Optional perf blades available at 2,4,6,8,12 TPI and MICROPERF – Optional slitting blade – Blades mounted on pressure adjustable holder, easily changeable – Optional stand Impression Control: Electronically variable; able to put a good impression on bond without embossing, while also being able to crash up to 10-part sets! Maximum amount of number positions: 10 number per head per sheet Electrical: 115V/60Hz/3A or 230V/50Hz/5A Stock Size: Minimum 3″ wide x 5″ long (7.6cm x 12.7cm)

Maximum 18″ wide x 18″ long (45cm x 45cm)Crash Capability: Electronically variable by dial control – Crash number up to 10 part sets Registration: 0.010″ (0.25mm) accuracy Maximum Number of Heads: 2 Head Rotation: Lockable in any position throughout 360 degrees Issue rendering sage

Operating at speeds up to 6000 sheets per hour, the “6000” makes fast and easy work of finishing needs.

• Feed sets unglued or glued side

• Accurate .010″ register

• 1 number per head per sheet -

Numbering System

GM-GWH-12000Additional Features:

12,000 standard-size sheets per hour 100-job memory to store numbering jobs Up to 100 numbering positions per head per sheet 1-4 PNEUMATIC numbering heads ** ** NB Pneumatic machines; compressor required but not supplied Heads rotate & lock throughout 360 degrees for perfect register 30 inch-long register board for easy set up & perfect register Floor model on castors; doesn’t need dedicated floor/table space Crash number up to 10-part sets Feed sets from the unglued or glued side Create “snap sets” while numbering Perforating options: 2,4,6,8,12 TPI Microperf options: 42 or 72 TPI Scoring options: wide (standard) or narrow Optional slitting blade available Ability to control depth of each perf/score/slit independently Accurate .010″ register Microprocessor controlled with forward & backward stepping for easy programming Speed: 12,000, 11 x 8.5″/A4 sheets per hour Maximum Stock Size: 18″ x 18″ (45 cm x 45 cm) Minimum Stock Size: 3″W x 5″L (7.6cm x 12.7cm) Stock Weight: 12# – 12 point (45 – 250 gsm) Impression Control: Electronically variable, crash up to 10-part sets Electrical: 120V/230V, 60/50Hz, 5.0 Amp Dimensions: Length: 68″ (1.73m)

Width: 27″ (0.69m)

Height: 46″ (1.17m)

Weight: 325 lbs. (135 kg)Number of job memories: 100 Maximum number of numbering positions: 100 per head per sheet Maximum number of heads: 4 Drive Unit Type: Pneumatic; compressor required but not supplied Head Rotation: Lockable throughout 360 degrees Repeat Action: Consecutive, 1x, 2x, 3x, 4x Numbering Heads: 6 digit reverse standard (with 2 drop) 8 digit condensed optional “No” and letter prefix available Inking System: Ink pad with reservoir Perforating Options: 2,4,6,8,12,16 teeth per inch (TPI), 42,50 and 72 Microperf TPI MICROPERF Options: 42 or 72 TPI Scoring blade options: Wide (standard) or narrow Slitting Blade: Optional Stand: Included Register: Microprocessor controlled to .010″ (0.25mm)

Issue rendering sage

The GW12000 has production speeds of 12000 sph while maintaining registration and accuracy. It has a 30 inch long register board, individually pressure adjustable perf/score/slit, tireless pneumatic heads, and a conveyor outfeed delivery.

• Up to 100 numbering positions per head per sheet

• Optional slitting blade available

• Heads rotate & lock throughout 360 degrees for perfect register -

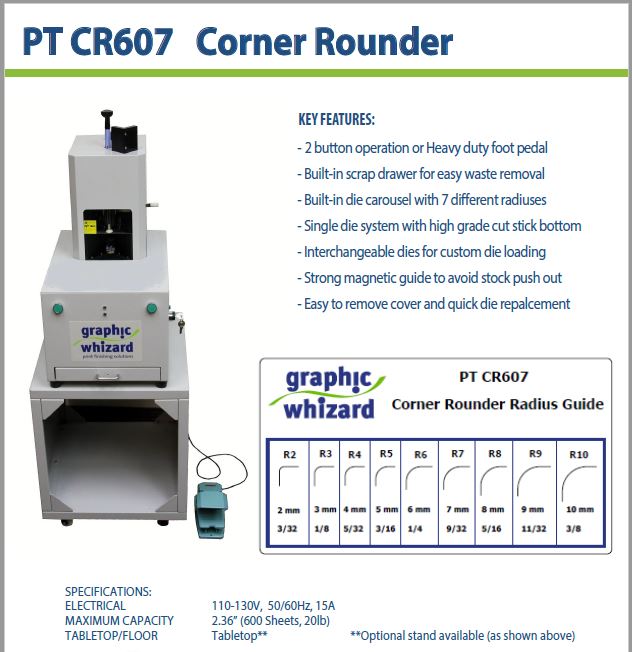

Corner Rounder CR607

GM-GWH-PTCR607The corner rounder from Graphic Whizard rounds up to 600 sheets of paper. Utilizing seven available dies on a built-in rotary carousel, jobs are quick and easy. Comes with optional floor stand.

• 2 button operation or heavy duty foot pedal

• Built-in scrap drawer for easy waste removal

• Built-in die carousel with 7 different radius'

• Single die system with high grade cut stick bottom

• Interchangeable dies for custom die loading

• Strong magnetic guide to avoid stock push out

• Easy to remove cover and quick die replacement

• 1 year warranty (does not include consumables)• Electrical: 110-130V, 50/60Hz, 15A

• Max Capacity: 2.36" (600 sheets, 20lbs)

• Table top/floor: Tabletop (optional stand available. As shown.)

Issue rendering sage

The corner rounder from Graphic Whizard rounds up to 600 sheets of paper. Utilizing seven available dies on a built-in rotary carousel, jobs are quick and easy. Comes with optional floor stand.

• 2 button operation or heavy duty foot pedal

• Built-in scrap drawer for easy waste removal

• Built-in die carousel with 7 different radius'

• Single die system with high grade cut stick bottom

-

GW Slitter Cutter Creaser

GM-GWH-PT331SCCKEY FEATURES:

- SLIT, CUT, CREASE OR PERF IN A SINGLE PASS

- 150-350 GSM

- INTERCHANGEABLE CREASE/ PERF DIES

- FULL OR PARTIAL CROSS PERF

- UP TO 32 CREASES/ PERFS IN ONE PASS

- REGISTRATION MARK CUT COMPENSATION

- PRESET PROGRAMS FOR QUICK JOB CHANGEOVER

- MANUAL CUT/CREASE INPUT FOR CUSTOMIZED JOBS

- EASILY CHANGE SLITTING FORMATS WITHOUT THE NEED OF REPLACING CARTRIDGES

Sheet Size: 8.27" x 8.27" to 14.5" x 26.75"

Stock Weights: up to 350gsm

Slitter: 4 units (6 blades: 2 margin blades & 4 gutter blades)

Creaser: Matrix creasing with adjustable depth

Cross Perforator: X-axis perforation (Included)

Scoring: (Option)

Feeder: Hand feed

Production Speed: 21 sheets/min (2 cuts & 1 crease)

Electrical: Single phase Standard 110VIssue rendering sage

The PT 331SCC slits, cuts, creases or perfs in a single pass. Full or partial cross perforate up to 32 creases/perfs with registration mark cut compensation. Slitting formats are easily changeable without the need of replacing cartridges

• 150-350 gsm

• Interchangeable crease / perf dies

• Preset programs for quick job changeover

• Manual cut/crease input for customized jobs -

GW Automatic Creaser Folding System

GM-GWH-PT335AFKThe GW PT335 AKF folds, creases up/down and cross perfs all in one machine. It features a 4" vacuum pile feeder, auto sheet measurement, a 6" color touchscreen and has 6 different interchangeable creasing/perfing dies.

• Speed: 6,500 sheets/hr

• Folds paper from 150 to 350 gsm

• Crease or perf up to 35" long sheets into one bypass

• Self-adjusting automated smart delivery

• Automated job set up with sheet length measuring

• Interchangeable dies for perforating with partial perf capabilities

• Interchangeable crease dies to compensate for stock thickness

• 3 year warrantyElectrical 110-130v, 50/60hZ, 15a Speed 6,500 sheets/set per hour

11″ x 8.5″ half foldMaximum Sheet Size 13″ wide x 35″ long

(33.02cm x 88.90cm)Minimum Sheet Size 5.5″ wide x 6″ long

(13.97cm x 15.24cm)Stock Weight 150-350 gsm Tabletop/Floor Floor Max Number of Creasing Positions 32 Program Memory 64 Feeder 4” vacuum pile feed NOTE: Machine performance will vary based on stock weight, type, and specifications of the job being performed.

Issue rendering sage

The GW PT335 AKF folds, creases up/down and cross perfs all in one machine. It features a 4" vacuum pile feeder, auto sheet measurement, a 6" color touchscreen and has 6 different interchangeable creasing/perfing dies.

• Speed: 6,500 sheets/hr

• Folds paper from 150 to 350 gsm

• Crease or perf up to 35" long sheets into one bypass

• Self-adjusting automated smart delivery

-

Multi Automatic Creaser

GM-GWH-PT335BIssue rendering sage

• Speed: 4500 SPH (Based on 8.5" x 11"run landscape, 1 crease)

• Maximum stock size: 13" x 25.5"

• Max # Crease Positions: 32

• Feeder: 4" Airfed vacuum pile feeder -

GW PT335 Multi Slitter Cutter Creaser

GM-GWH-PT335SCCThe new PT335 SCC Multi is a complete full-bleed finishing system to fit the digital marketplace. Equipped with interchangeable creasing/ perfing dies, the PT 335SCC Multi can quickly switch over from perfing to creasing while preventing digital toner cracking. Strike perf capabilities means that the PT 335SCC Multi can now do partial perfs in both directions for "T" or "box" perfs. The PT335 SCC Multi ideal in making business cards, greeting cards, invitations, brochures, pamphlets, catalogs, posters, book/CD covers, photographs, tent cards, and more.

Key Features

- 4" deep pile feeder

- Multi Accessory Output

- 9" color touchscreen

- Interchangeable crease/perf dies

- Built in job creator

- 64 job program memory

- Strike perf capabilities for "box" or "T" perfs

- Automated crease depth adjustment

Size: Min is 8.26" x 8.26" and Max is 13" x 26.5" (40" handfed)

Stock Weights: 150- 350gsm/ 16pt.

Slitter: Up to 6 slits

Creaser: Up to 32 creases or perfs per sheet

X and Y axis: Image shift, shrink, stretch compensation

Production Speed: 25 sheets per minute (8.5" x 11" 2 cuts, 1 crease)

Margin Slit: Side trim 0.125” – 1.5”

Gutter Slit: Width 0.2” – 0.59” *larger gutters will output on exit tray

Electrical: 110-130V, 50/60Hz, 15A

Interchangeable Perf Dies: 12 Tpi, 24 Tpi or 8 depth

Interchangeable Crease Dies: 0.6mm, 1mm, 1.2mm or 1.4mmIssue rendering sage

The new PT 335SCC Multi is a complete full-bleed finishing system to fit the digital marketplace. Equipped with interchangeable creasing/ perfing dies the PT 335SCC Multi can quickly switch over from perfing to creasing while preventing digital toner cracking. Strike perf capabilities means that the PT 335SCC Multi can now do partial perfs in both directions for “T” or “box” perfs.

• 4" deep pile feeder

• Multi Accessory Output

• 9" color touchscreen -

GW PT8336 SCC Auto Feed/Slit Creasing System

GM-GWH-PT8336SCCThe PT 8336SCC Multi is a complete full-bleed finishing system designed for the digital marketplace. Equipped with interchangeable creasing/perfing dies, the PT 8336SCC Multi can quickly switch from perfing to creasing to prevent digital toner cracking. Strike perf capability alloys that the PT 8336SCC Multi to do partial perfs in both directions for “T” or “box” perfs.

The PT 8336SCC Multi makes short work of; business cards, greeting cards, invitations, brochures, pamphlets, catalogs, posters, book/CD covers, photographs, tent cards, and more by simply loading the high capacity 4” vacuum pile feeder. Processing sheets up to 400 gsm at speeds of 25 sheets per minute (8.5” x 11”, 2 cuts, 1 crease) the PT

8336SCC Multi is an ideal finishing solution to maximize efficiency while minimizing operator intervention.- 25 sheets per minute

8.5” x 11” 2 cuts, 1 crease - 110-130V, 50/60Hz, 15A

- EFI Fiery Driven print engine

- Save up to 70% in set up time, reduce cost & waste

- Minimum 8.26″ wide x 8.16″ long (20.98cm x 20.72cm)

Maximum 13″ wide x 26.5″ long (33.02cm x 67.31cm) 40” handfed (104 cm)

Feed Capacity 4″ Feeder Type Air suction Pile Feeder Input Paper Weight 150-400gsm Input Paper Size 8.26″ x 8.16″ (20.98cm x 20.72cm)

13”x 26.5” (33.02cm x 67.31cm)

40” Hand Fed (104cm)Minimum finished cut size 1.96″ x 1.89″ Speed Up to 25 sheets per minute Crease Depth Adjustment 5 steps auto adjust Crease Width Options 4 .6, 1, 1.2, 1.4 mm Crease Direction Up or Down Number of Slitters 6, variable gutters Integrated Conveyor Outfeed Option Yes Cut Mark Image Shift Compensation Yes (Lead and side) Linear Perforating Yes Strike Perf Option Yes Cross Perforating Yes Micro Perforating Yes 24/48 TPI Custom Job Memory 64 Double Sheet Detect Yes Ultrasonic Bar Code Job Recognition Yes 9″ Color Touchscreen Yes Built in Job Creator Yes Warranty 3 year parts and electron Issue rendering sage

The PT 8336SCC Multi is a complete full-bleed finishing system designed for the digital marketplace. Equipped with interchangeable creasing/perfing dies, the PT 8336CC Multi can quickly switch from perfing to creasing to prevent digital toner cracking.

• 4" deep pile feeder

• Multi accessory output

• 9" color touchscreen

• Built in job creator and 64 job program memory

- 25 sheets per minute

-

GW PT33LSC Automated Laminator

GM-GWH-PT33LSCLaminate, slit and cut with the GW PT 33LSC. Designed for the digital short-run printer, the PT 33LSC cuts to bleed as well as has variable size encapsulation mode.

• Slits and cuts to size

• Film choices of gloss, matte, soft touch and more

• Pouch mode with variable encapsulation size

• Anti-curl device

• Automatic setup and program memory

• 2" vacuum pile feeder

• Multiple laminating modes

• Variable speedsElectrical 110-130v, 50/60Hz, 15A Floor Model Yes Speed Variable speeds up to 10 feet per minute Minimum Sheet Size 7″ x 7″ (17.78 cm x 17.78 cm) Maximum Sheet Size 13″ x 19.7″ (33.02 cm x 50.038 cm) (Up to 27″ dependent on programmed mode) Paper Thickness 100-350 gsm Lamination Thickness 1.5, 3 & 5 mil* Lamination Width 4.4″ – 12.9″ (11.176 cm – 32.766 cm)* custom widths available Laminating Modes Double-sided, single-sided with anti-curl device (no need for release film), encapsulation, and trim to bleed Cutting Method 2 automatic setup side slitters and 1 guillotine cutter assembly Feeding Method 2″ (5.08 cm) vacuum pile feeder *Film weight compatibility varies with laminating mode.

NOTE: Machine performance will vary based on stock weight, type, and specifications of the job being performed.

WARRANTY: 3 year warranty* (* excludes consumables)Issue rendering sage

Laminate, slit and cut with the GW PT 33LSC. Designed for the digital short-run printer, the PT 33LSC cuts to bleed as well as has variable size encapsulation mode.

• Slits and cuts to size

• Film choices of gloss, matte, soft touch and more

• Pouch mode with variable encapsulation size

• Anti-curl device

-

SinaJet DF0604 Digital Die Cutter

GM-GWH-D0604MTKiss cut, rotary cut, pen, crease, perf

Designed for the “on-demand” creation of folders, rounded business cards, greeting cards, self-adhesive labels, counter displays, cases, boxes customized in shape and style. All this in a simple, fast, and precise machine without waiting to create expensive and elaborate dies. Jobs will be processed effortlessly thanks to the 600 x 400 job format which is automatically loaded by the high pile feeder.

The Graphic Whizard digital flatbed cutter is the only one in the market of automatic plotters with Interchangeable Tools for specific and professional processes to handle not only prototyping, but also for small production. Capable of handling plasticized prints (up to 10mm with oscillating cut with the MT model) sheets are automatically managed allowing for unparalleled operator freedom. Interchangeable tools allow for cutting, kiss-cutting, creasing and perforation.

- 1000mm per second

- 208-240V, 50/60Hz, 30 A single phase

- Minimum sheet size: 210 mm x 297 mm / 8″x12″

- Maximum sheet size: 680 mm x 420 mm / 26.8″ x 16.5″

- Maximum cutting area: 600 mm x 400 mm / 23.6″x15.75″

- Up to 1.8mm

- 7″ pile height with suction adjustment

- Roll feed option for vinyl or labels

- Interchangeable tools for a variety of custom applications

- Built-in compressor

- Barcode and 4 corner registration mark reading

Pwr Requirement 208-240V, 50/60Hz, 30 A single phase Feeder pile height capacity 180 mm / 7″ Max. Sheet Size (Auto feed) 680 mm x 420 mm / 26.8″ x 16.5″ Max. Cutting Area 600 mm x 400 mm / 23.6″x15.75″ Max. Cutting Speed 1,000 mm/second Cutting Thickness Up to 1.8 mm Recommended cutting material Cardstock, Paper, Labels Number of tool locations 3 Standard tools included Dual RCT (Rotary Cutting Tool) RST (Rotary Scoring Tool) Interchange RTC with Ballpoint Pen or Crease Pen EOT Electronic Oscillating Tool No ACT Active Circular Tool (Fabric) No Roll feed option Yes Infrared anti-collision device No Compressor required Yes, built in Cutting and Camera Software Sinajet Control Center QR Code Reader Yes Barcode Reader Yes CCD Camera Positioning Yes Cutting Tolerance +/- 0.1mm Min. Paper Weight 80 gsm/70 lb. text Dimensions 3123 (L) x 1090 (W) x 1170(H) mm 123″ (L) x 43″ (W) x 46 “(H) Machine weight 450 kg / 990 lbs Issue rendering sage

Designed for the "on-demand" creation of folders, rounded business cards, greeting cards, self0adhesive labels, counter displays and customized boxes in any shape and style. The only one in the market with automatic plotters with Interchangeable Tools for prototyping and small production.

• Cutting speed: 40" per second

• Minimum sheet size: 8"x12"

• Maximum cutting area: 23.6" x 15.75"

• Feeder pile capacity: 7"

• Cutting, kiss-cutting, creasing and perforation

• Control Center Software provided with Sinajet