-

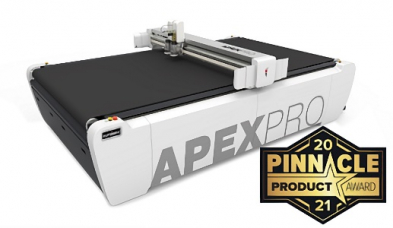

Apex 1312 Pro Digital Cutting System

GM-CWT-1312

The Award Winning Apex Pro 1312 Digital Flatbed Cutter with a cutting area of 43 inches x 51 inches is designed for a variety of processing and finishing production needs for visionary PSP, packaging, sign & graphics, POP/POS display and textile market professionals. Increase your productivity and profitability by having a multi-function digital cutting solution in-house.

• 1312 series: 43" x 51" effective cutting area

• Precise Automatic Positioning system (option)

• Optical Auto Tool calibration (option)

• 4.9 ft/s max cutting speed -

Apex Plus 1516 Digital Flatbed Cutter

GM-CWT-1516

The Apex Plus series of digital flatbed cutters are versatile cutting solutions for a wide range of industries, including graphics, packaging, textile, and upholstery. They offer precision, speed, and versatility, making them ideal for in-house cutting operations. With the Apex Plus series, you can cut, crease, decal cut, and oscillate cut a variety of materials, increasing your productivity and profitability. The Apex series is backed by over 27 years of experience in engineering cutting tables. This experience ensures that the Apex Plus series is designed for reliability and performance.

• 1516 series: 63”x 59” effective cutting area

• Optical Auto Tool calibration

• Aircraft aluminum table for precision and accuracy -

Apex 2513 Digital Cutting System

GM-CWT-2513

The Apex series of digital die cutters are designed for a variety of finishing requirements. Increase productivity and profitability by having an in-house, multi-functional precision high speed digital cutting solution that can cut, crease, decal cut, oscilate cut materials.

• Available in 3 standard sizes and custom sizes

• 2513 Series: 51" x 98" cutting area

• True 3 tool positions available

• Optical Auto Tool calibration -

Apex 2516 Pro Digital Cutting System

GM-CWT-2516

The Award Winning Apex Pro 2516 Digital Flatbed Cutter with a cutting area of 63 inches x 98 inches is designed for a variety of processing and finishing production needs for visionary PSP, packaging, sign & graphics, POP/POS display and textile market professionals. Increase your productivity and profitability by having a multi-function digital cutting solution in-house.

• 2516 series: 63" x 98" effective cutting area

• Precise Automatic Positioning system (option)

• Optical Auto Tool calibration (option)

• 4.9 ft/s max cutting speed

-

Eclipse 1523 Digital Die Cutter

GM-CWT-EC1523

The Eclipse die free flatbed cutting solution is designed for the Printing, Sign and Packaging industries. It is a cost-effective solution for sample making and short-run production of adhesive sheets, business cards, invitations, labels, small packaging, tags and more.

• Decal cut, oscillate, cut, kiss cut, and crease

• Handles sheets up to 15.5" x 26.5"

• Cuts foam core, PVC, cardboard and more

• 2 knife positions, 1 creasing tool, 1 electronic oscillating tool

• CCD Camera registration

-

Eclipse 2029 Digital Die Cutting Machine

GM-CWT-ECLIPSE_M

The Eclipse 2029 Digital Die Cutter is a die free flatbed cutting solution designed for the printing, packaging, and sign

industries. It is a cost-effective solution for sample making, short-run production of adhesive sheets, business cards,

specially shaped cards, invitations, labels, small packaging, tags, and more.

• Up to 4 tools on a single sheet

• 4kw vacuum power absorption

• Oscillating tool for up to 6mm thick materials -

Eclipse 1007 Digital Die Cutter

GM-CWT-ECLIPSE_X

The Eclipse 1007 Digital Die Cutter is a die free flatbed cutting solution designed for the printing, packaging, and sign industries. It is a cost-effective solution for sample making, short-run production of adhesive sheets, business cards, specially shaped cards, invitations, labels, packaging, tags, and more. The Eclipse 1007 features an integrated touch Screen PC for full operation at your finger tips. Process materials up to 10mm thick and up to B5 (35"x47") sheet size. Use the roll feed attachment for 24" wide roll material processing.

• Automatic feeding system

• Up to 5 tools on a single sheet

• Integrated roll feed attachment

-

Matrix Omni-Flow 330 (SRA3) Deep Pile Feeder

GM-CWT-OMNI330The Matrix Omni-Flow Deep Pile Feeder is a modular system that is designed to be simple to install, configure and operate. The feeder can be retro-fitted to any Matrix Pneumatic or Matrix Duplex model.

• Retrofits all Matrix pneumatic and duplex models

• Quick and easy set-up and operation

• Fully automatic lamination and foiling

• Change between paper stocks in seconds -

Flexa Easy Lite Air Heat Assisted Top Roller Laminator

GM-CWT-FLX_AIRIntroducing the Flexa Easy Lite Air: a professional heat-assisted top roller laminator specifically engineered for self-adhesive materials. This innovative device not only laminates but also facilitates mounting with ease. Crafted entirely in Italy, it epitomizes quality and precision in design and manufacturing.

• Cost-Effective

• Working Flexibility

• Easy to Use Control Panel -

Flexa Easy Lite Heat Assisted Laminator w/WiFi

GM-CWT-FLX_WIFIThe Flexa Easy Lite is a heat assisted laminator for wide-format media that has built-in Wi-Fi/LAN. You can use your PC or mobile devices to remotely monitor the machine data and working parameters. The software has a modern graphic design that lets you easily use the many new functions, such as saving three different processes, measuring the laminated meters, setting the automatic shutdown, scheduling the switch on and off times and more.

• Remote monitoring

• Easy to use

• No material waste -

Cutworx FL13 Laminator & Foiler

GM-CWT-FL13If you are looking for a professional foiler and laminator that can handle most printed media up to 13 inches, the Cutworx FL13 is the perfect choice. It is designed for print shops that want to offer fast and efficient foiling or laminating for small batches.

• Hot roller technology

• Speed and temperature control

• Laminates top hot -

Express Heat-Assisted Laminator

GM-CWT-EXPA high-grade top roller laminator designed specifically for self-adhesive materials, featuring heat assistance. This versatile device enables laminating, mounting, and encapsulating with precision. Engineered for reliability and user-friendliness, it ensures flawless, high-quality results every time.

• Adjustable Laminating Pressure

• Foot Pedal For Hands Free Operation

• Photosensitive Safety Cells