-

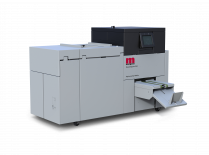

Morgana BM4035 Bookletmaker

GM-PLO-BM4035

A new kind of booklet maker that can produce A4 landscape or large format 297mm x 297mm books. Includes a corner and edge stapling function as standard

• Produce square folded booklets from A6 to A4 Landscape, or large format 297 x 297mm

• Corner stapled documents in portrait A4

• Edge stapled documents in portrait and landscape A4

• Up to 140 page booklet capacity

• Supports up to 660mm long sheets without CST or 620mm with CST

-

Morgana BM4050 Bookletmaker

GM-PLO-BM4050

A new kind of booklet maker that can produce A4 landscape or large format 297mm x 297mm books. Includes a corner and edge stapling function as standard

• Produce square folded booklets from A6 to A4 Landscape, or large format 297 x 297mm

• Corner stapled documents in portrait A4

• Edge stapled documents in portrait and landscape A4

• Up to 200 page booklet capacity

• Supports up to 660mm long sheets without CST or 620mm with CST -

Morgana BM5035 | BM5050 Bookletmaker

GM-PLO-BM5050 The all NEW Morgana BM5000 series is the latest member of the Plockmatic Group booklet making family. Engineered for mid-to-high volume customers with the highest quality and functionality requirements.

The all NEW Morgana BM5000 series is the latest member of the Plockmatic Group booklet making family. Engineered for mid-to-high volume customers with the highest quality and functionality requirements.

• Produces landscape and oversize sizes

• Handles 620mm/24.5" long sheets

• Finish 50 sheets, 2-up w/ 4 stitching heads

• Higher productivity and efficiency -

Morgana PowerSquare 224VF

GM-MSY-PSQ224FR The NEW PowerSquare™ 224VF with its high capacity dual bin feeder offers a flexible solution for a wide range of booklet types and sizes.

The NEW PowerSquare™ 224VF with its high capacity dual bin feeder offers a flexible solution for a wide range of booklet types and sizes.

• Makes books from 4 – 224 pages

• Fast and cost-effective

• Produces high quality SquareBack™ Books

• Inserts 1-6 stitches

• Small footprint -

Morgana AutoFold Pro

GM-MSY-AUTOFOLD Controlled by the same innovative 7″ SmartScreen panel as other machines in the Pro range, the AutoFold Pro is instructed how long the pre-creased sheet is and which fold to produce.

Controlled by the same innovative 7″ SmartScreen panel as other machines in the Pro range, the AutoFold Pro is instructed how long the pre-creased sheet is and which fold to produce.

• SmartScreen touch screen operation

• Alpha-numeric memory

• Highly versatile

• Immediately improve productivity and quality -

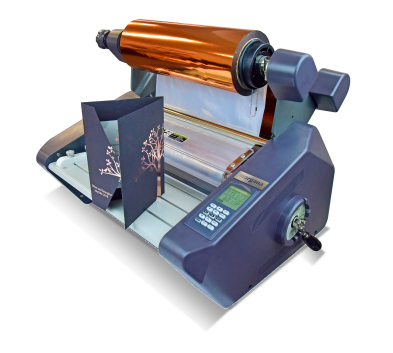

Morgana 1200LX ColorFlare Foiling and Laminating System

GM-MSY-CF1200LXThe Morgana CF1200 ColorFlare series delivers superb foiling, lamination and holographics. Featuring the easy-to-use touch control panel, and the innovative ‘burst separation’ system ensuring clean perpendicular trims between sheets. Current models now also ship with the up-rated air compressor and new ‘pull roll control’ function for improved foiling results.

• Lamination pull roll control

• Advanced dual process for lamination and foil flaring technologies for digital applications

• Multiple jobs and flaring effects possible with just 1 machine -

Foiling, lamination and flaring effects are possible with this single desktop solution. Offering class-leading affordability, CF350 uses 3″ (77mm) core rolls providing a more cost effective production solution. This simple in-house process requires no expensive blocks or dies.

• Handles media up to 13″ wide

• Easy continuous feed

• Adjustable pressures for different applications -

The Morgana ColorCut LC600 ‘on demand’ digital sheet label cutter is designed to provide automatic sheet label cutting for digital print production users, with NO die’s or setup costs.

• Digital process means no more costly dies

• QR code/Job Library retrieves associated cut files – even for mixed job batch sessions

• Auto stacker/feeder takes up to 250 sheetsUS$POA -

Morgana Intec ColorCut SC6000 Feeder & Cutting System

GM-MSY-SC6000_110

Perfect for digitally die-cutting packaging, P.O.S. and lightweight card projects – as well as kiss-cutting sheet labels – the all NEW Morgana Intec SC6000 is an ‘on demand’ digital sheet cutter with no physical dies or time-consuming setup costs.

• Cut speeds up to 37.8"/sec

• Digital process means no more costly dies or wasted waiting time

• Auto feeder stacks up to 1,000 80gsm sheets.

• ColorCut Pro – Production Studio software includedUS$POA -

Morgana Intec ColorCut SC6500 Feeder & Cutting System

GM-MSY-SC6500_110

Perfect for digitally die-cutting packaging, P.O.S. and lightweight card projects – as well as kiss-cutting sheet labels – the all NEW Morgana Intec SC6500 is an ‘on demand’ digital sheet cutter with no physical dies or time-consuming setup costs. Send repeat jobs to a USB drive, enabling you to remotely cut your jobs anywhere there is a power outlet (NO WIRES).

• Cut speeds up to 37.8"/sec

• Digital process means no more costly dies or wasted waiting time

• Auto feeder stacks up to 1,000 80gsm sheets.

• ColorCut Pro – Production Studio software included

• Runs off USBUS$POA -

Morgana Intec ColorCut Server Station

GM-MSY-FBCCSTIntec ColorCut Server Stations are the central hub of ColorCut’s cutting ecosystem – connecting to each networked graphic designers’ system and integrating with the print/finishing room for seamless workflow automation.

• Production Studio 4 is the core operating software

• Template Maker enables designers to create simple cartons and shaped items

• Job Library Manager sophisticated job managementUS$POA -

Morgana Intec ColorCut FB9000 Pro Auto Cutting System

GM-MSY-FB9000PRO_110 The all NEW Morgana Intec FB9000 is an advanced, fully automated digital die cutter delivering lightning speed performance, unparalleled media control in a user-friendly format.

The all NEW Morgana Intec FB9000 is an advanced, fully automated digital die cutter delivering lightning speed performance, unparalleled media control in a user-friendly format.

• Easy set up and use

• Stacks 2,000 80gsm sheets

• Dual tool head contains highest resolution CCD camera

• ColorCut Pro software includedUS$POA