- Home /

- Finishing /

- Die Cutters

Categories: Die Cutters

Filter Results

Quality die cutters available online at Print & Finishing Solutions.

-

Cutworx MCT Rotary Die Cutter

GM-CWT-MCTThe MCT Rotary Die Cutter, an innovative solution for small batch and multiple repeat production, excels in creating self-adhesive stickers, wine labels, garment hangtags, playing cards, and more.

• Small footprint saves space

• Accurate and fast feeding

• Safer blade changing > Learn More -

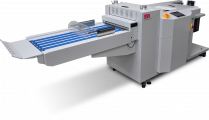

Dynacut Rotary Die Cutter w/Feed & Exit Tray

GM-MYA-RD435

The most affordable rotary die cutter on the market today. No more expensive dies required.

• Easy set up and use

• 8" stacking capacity; 435gsm

• Feeds up to 14 x 20" paper sizes

• Made in the USA

> Learn More -

Morgana Rotary Die Cutter

GM-PLO-RDC The RDC is the ideal machine for the production of high volumes of boxes, labels and personalized items, such as business cards, greetings cards and postcards. Designed to meet today's digital print applications.

The RDC is the ideal machine for the production of high volumes of boxes, labels and personalized items, such as business cards, greetings cards and postcards. Designed to meet today's digital print applications.

• Easy to use touch screen

• Controlled Accuracy

• Produce 4,000 sheets/hr

• Supplied with or without sheet separator > Learn More -

Horizon RD 3346

GM-HOR-RD3346 The RD-3346 Rotary Die-Cut System meets the growing demand for short-run applications and is well suited for small applications such as tags and business cards.

The RD-3346 Rotary Die-Cut System meets the growing demand for short-run applications and is well suited for small applications such as tags and business cards.

• Speeds up to 5,000 cycles/hr

• Up to 0.013" in thickness > Learn More -

Horizon RD 4055

GM-HOR-RD4055 The Horizon RD-4055 Rotary Die Cutter is designed to meet the growing demand for short-run die-cut product with its ability to die-cut, crease, perforate, slit, hole punch, and round corner in one process for digital and offset printed sheets.

The Horizon RD-4055 Rotary Die Cutter is designed to meet the growing demand for short-run die-cut product with its ability to die-cut, crease, perforate, slit, hole punch, and round corner in one process for digital and offset printed sheets.

• Easy to use touch screen

• Double-feed detection

• Simultaneous cuts

• Eliminate image cracking

• Reduce costs > Learn More -

Horizon RD-N4055 Rotary Die Cutter

GM-HOR-RDN4055

The Horizon RD N4055 Rotary Die Cutting machine combines a high-capacity feeder, a single- or dual-magnetic cylinder die cutter, a specially designed separator, and an optional card stacker into a highly efficient, versatile system for operator-friendly production. It features a modular design allowing for simultaneous die-cutting, kiss-cutting, creasing, and perforating operations. The machine also advanced features driven by servo technology for precise registration and positioning, multi-up applications from a single-up die to automatic waste removal.

• Kiss-cut and die cut simultaneously

• Production speed: 6,000 cycles/hr

• Up to 400gsm

• Increase productivity by 20% > Learn More -

Horizon RD 4055DMC Rotary Cutter w/Dual Magnetic Cyl

GM-HOR-RD4055DMC The Horizon RD-4055DM Rotary Die Cutter with dual magnetic cylinders is designed to simultaneously die-cut and crease/ score short-run product from both sides of the sheet.

The Horizon RD-4055DM Rotary Die Cutter with dual magnetic cylinders is designed to simultaneously die-cut and crease/ score short-run product from both sides of the sheet.

• Size:7.875” x 10.830” – 15.740” x 21.650”

• Feeder Stacker Height: 19.68”

• Speed: 6,000 cycles/hr

• Thickness: 127.9 to 400gsm > Learn More -

Apex PRO 1516 Digital Flatbed Cutter 63" x 59"

GM-CWT-1516PRO

The Award Winning Apex Pro 1516 Digital Flatbed Cutter with a cutting area of 63 inches x 59 inches is designed for a variety of processing and finishing production needs for visionary PSP, packaging, sign & graphics, POP/POS display and textile market professionals. Increase your productivity and profitability by having a multi-function digital cutting solution in-house.

• 1516 series: 63" x 59" effective cutting area

• Precise Automatic Positioning system (option)

• Optical Auto Tool calibration (option)

• 4.9 ft/s max cutting speed > Learn More -

Apex 1312 Pro Digital Cutting System

GM-CWT-1312

The Award Winning Apex Pro 1312 Digital Flatbed Cutter with a cutting area of 43 inches x 51 inches is designed for a variety of processing and finishing production needs for visionary PSP, packaging, sign & graphics, POP/POS display and textile market professionals. Increase your productivity and profitability by having a multi-function digital cutting solution in-house.

• 1312 series: 43" x 51" effective cutting area

• Precise Automatic Positioning system (option)

• Optical Auto Tool calibration (option)

• 4.9 ft/s max cutting speed > Learn More -

Apex Plus 1516 Digital Flatbed Cutter

GM-CWT-1516

The Apex Plus series of digital flatbed cutters are versatile cutting solutions for a wide range of industries, including graphics, packaging, textile, and upholstery. They offer precision, speed, and versatility, making them ideal for in-house cutting operations. With the Apex Plus series, you can cut, crease, decal cut, and oscillate cut a variety of materials, increasing your productivity and profitability. The Apex series is backed by over 27 years of experience in engineering cutting tables. This experience ensures that the Apex Plus series is designed for reliability and performance.

• 1516 series: 63”x 59” effective cutting area

• Optical Auto Tool calibration

• Aircraft aluminum table for precision and accuracy > Learn More -

Apex 2513 Digital Cutting System

GM-CWT-2513

The Apex series of digital die cutters are designed for a variety of finishing requirements. Increase productivity and profitability by having an in-house, multi-functional precision high speed digital cutting solution that can cut, crease, decal cut, oscilate cut materials.

• Available in 3 standard sizes and custom sizes

• 2513 Series: 51" x 98" cutting area

• True 3 tool positions available

• Optical Auto Tool calibration > Learn More -

Apex 2516 Plus 3-Head Cutting System

GM-CWT-2516P

The Apex Plus series of digital flatbed cutters are designed for a variety of finishing requirements for Graphics, Packaging, Textile, & Upholstery Markets and more. Increase your productivity and profitability by having an in house multi-functional precision high speed digital cutting solution that can cut, crease, decal cut and oscillate cut materials. The Apex series is designed with over 27 years of experience engineering cutting tables.

• Multiple Table Size Solutions to match application

• True 3 tool positions available with all tool combinations

• Tool Head Modules controlled independently > Learn More